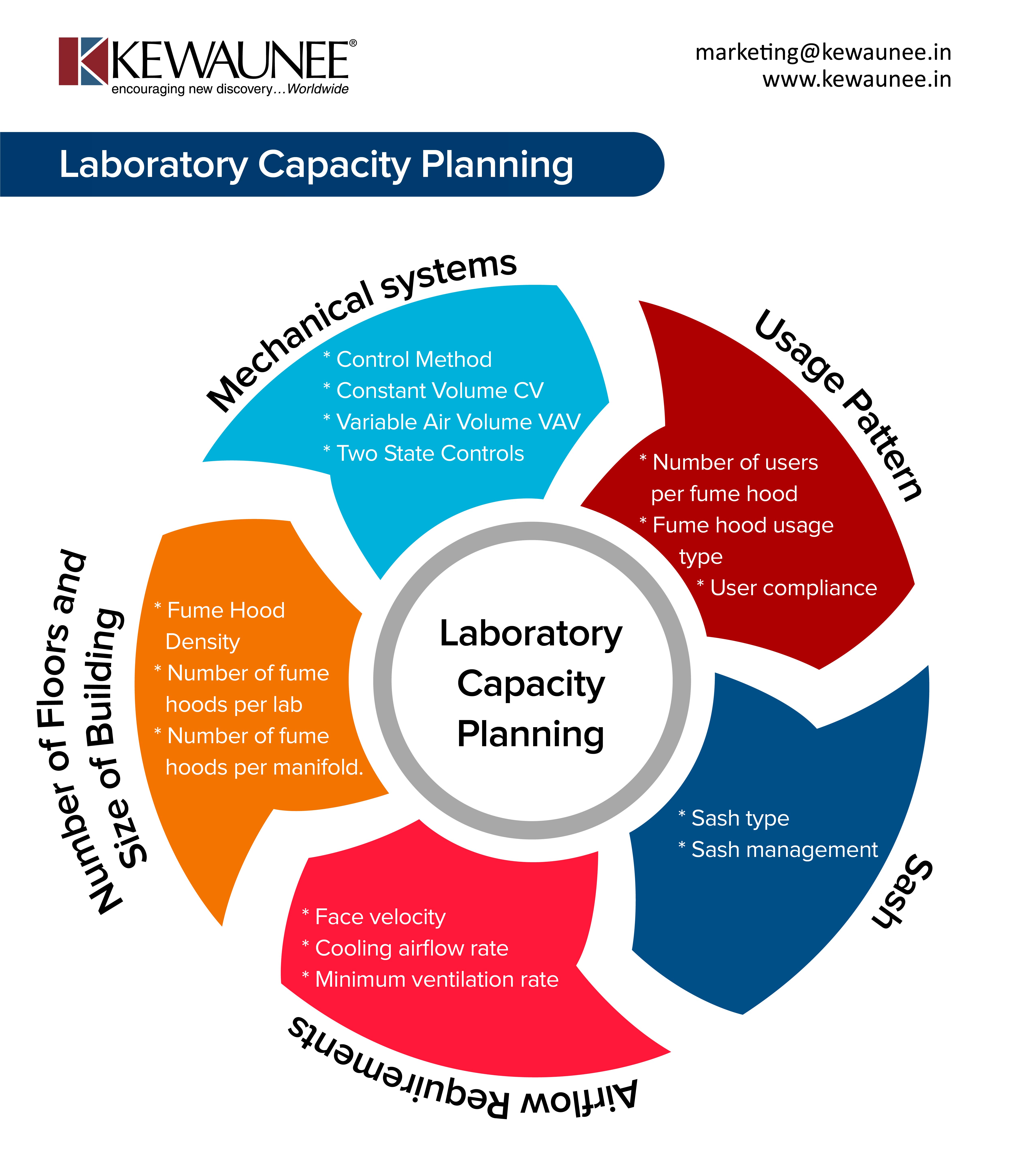

Laboratory Capacity Planning

HVAC is one of the significant operating expense in a laboratory. Laboratories can benefit from designing their capacity properly, right at the planning stage, and making provisions for expansion with no costly alterations.

Diversity is a design paradigm which will help to build optimal laboratories. According to SEFA, “Diversity is used by engineers in designing systems based on its practical or maximum expected use, not its total possible use. When diversity is applied to sizing of systems, the design capacity is less than the sum of peak demands”.

Diversity can benefit both the existing and new facilities:

- reduce capital equipment expenditures by downsizing the mechanical systems during the design phase,

- allows existing facilities to add fume hood capacity using the current HVAC systems.

The key factors influencing diversity are:

| Mechanical systems |

|

| Usage Pattern |

|

| Sash |

|

| Airflow Requirements |

|

| Number of Floors and Size of Building |

|

Whether your project is a brand-new multi-story research centre, or the remodel of an existing lab, Kewaunee provides the full range of services from design and engineering, through the final installation and start-up.

Comments are closed.