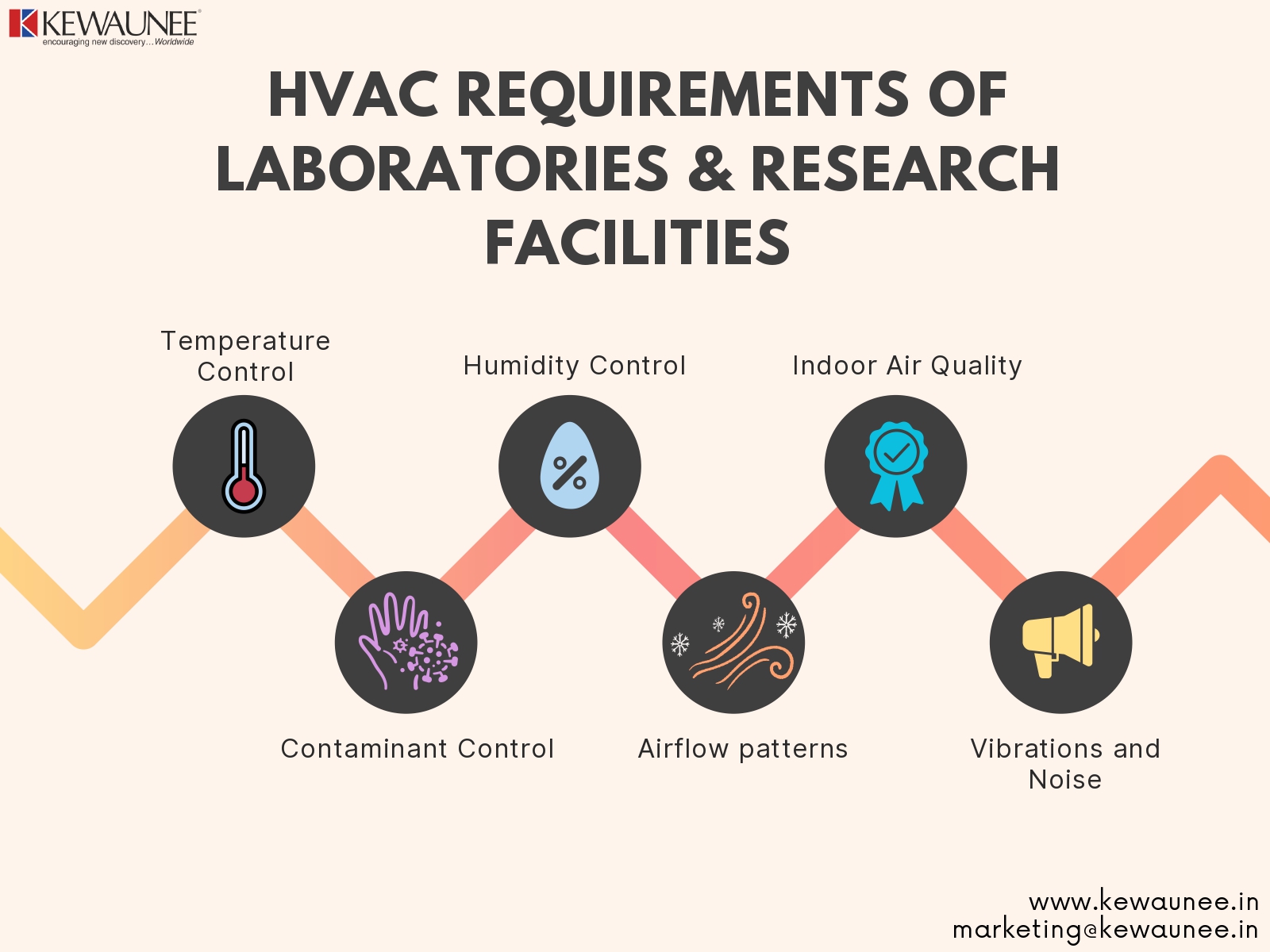

Unique HVAC Requirements of Laboratories & Research Facilities

HVAC (Heating, Ventilation, and Air Conditioning) systems play a crucial role in research facilities by providing a controlled environment necessary for various scientific processes. These systems are responsible for maintaining optimal temperature, humidity, and air quality, ensuring the integrity of experiments, the safety of researchers, and the protection of sensitive equipment and samples. Without proper HVAC design and operation, research outcomes can be compromised, and the well-being of occupants can be at risk.

Research facilities have specific HVAC requirements that differ from typical commercial or residential buildings. They often involve complex processes, hazardous materials, and specialized equipment, demanding a higher level of control and safety.

Temperature and humidity control are critical for maintaining stability and accuracy in experiments, while ventilation is essential for maintaining indoor air quality and removing airborne contaminants. Additionally, research facilities require advanced filtration systems and specialized design considerations to address unique challenges and ensure optimal performance.

The Role of HVAC in Research Facilities

A. Importance of temperature and humidity control

Precise temperature control is essential in research facilities to provide a stable and controlled environment for experiments. Many scientific processes are highly sensitive to temperature variations, and even slight deviations can lead to inaccurate results or failed experiments. Similarly, humidity control is crucial, as excessive moisture or dryness can affect the integrity of samples, equipment performance, and the growth of microorganisms.

B. Ventilation requirements for indoor air quality

Proper ventilation is vital to maintain indoor air quality in research facilities. Effective ventilation systems help remove contaminants, odors, and potentially harmful gases generated during experiments. They also control the concentration of airborne particles, ensuring a clean and safe working environment for researchers.

C. Contaminant control and filtration

Research facilities often deal with hazardous materials, volatile chemicals, or biological agents that require effective contaminant control measures. HVAC systems in these settings should incorporate specialized filtration systems, such as high-efficiency particulate air (HEPA) filters, to capture and remove airborne contaminants. This prevents cross-contamination, protects researchers from exposure, and maintains the integrity of experiments.

Understanding Research Facility Environments

A. Variability in research activities and requirements

Research facilities encompass a wide range of scientific disciplines and activities, each with its unique requirements. From biomedical research to material sciences, the HVAC design must consider the specific needs of the research being conducted. For example, cleanrooms used in semiconductor manufacturing require stringent control of airborne particles, while biological laboratories require containment systems to prevent the release of pathogens.

B. Types of research facilities (e.g., laboratories, cleanrooms)

Research facilities can include various types of laboratories, cleanrooms, animal research facilities, and specialized research spaces. Each type has specific HVAC considerations. Laboratories may require different airflow patterns and ventilation rates depending on the research conducted. Cleanrooms demand a high level of cleanliness and controlled environments with low particle counts. Animal research facilities require specialized ventilation systems to maintain the health and well-being of research animals.

C. Specific HVAC challenges in different research settings

Different research settings present unique HVAC challenges. For example, in vivariums, maintaining specific temperature, humidity, and ventilation conditions for animal welfare is critical. Molecular biology labs dealing with sensitive genetic materials may require special precautions to prevent cross-contamination. Understanding these challenges allows HVAC professionals to tailor the design and operation of the systems to meet the specific requirements of each research setting.

HVAC Design Considerations for Research Facilities

A. Zoning and specialized areas

Research facilities often have distinct areas with different HVAC requirements. Zoning allows for the customization of temperature, humidity, and ventilation parameters based on the needs of each zone. For example, offices, equipment rooms, and laboratories may have different temperature and ventilation requirements.

B. Airflow patterns and directional control

Controlling the direction of airflow is crucial in research facilities. Unidirectional airflow, such as laminar flow, can be necessary in specific areas to prevent cross-contamination or protect sensitive equipment. Understanding the airflow patterns and designing the HVAC system accordingly ensures the desired level of air movement and control throughout the facility.

C. Containment strategies for hazardous materials

When working with hazardous materials, such as biohazards or chemicals, containment strategies are essential for ensuring the safety of researchers and preventing the release of dangerous substances. HVAC systems can incorporate containment measures, such as negative pressure zones and specialized exhaust systems, to control and capture hazardous materials, minimizing the risk of exposure.

D. Reducing vibrations and noise

Certain research equipment and processes are sensitive to vibrations and noise. HVAC systems should be designed to minimize vibrations that can impact the accuracy and precision of experiments. Additionally, noise control measures, such as acoustic insulation and vibration isolation, help create a quieter and more comfortable working environment for researchers.

Ventilation Systems in Research Facilities

A. Air change rates and dilution ventilation

Proper ventilation rates are crucial for research facilities to maintain a healthy and safe environment. Air change rates determine how frequently the air in a space is replaced. Higher air change rates help dilute contaminants and maintain air quality. The required air change rates depend on the specific activities, occupancy, and potential contaminants present in the facility.

B. Fume hoods and local exhaust ventilation

Fume hoods are essential components of research facility ventilation systems, especially in chemical laboratories. These hoods capture and remove hazardous fumes, gases, and volatile chemicals generated during experiments. Local exhaust ventilation systems are designed to capture contaminants at the source, minimizing their dispersion in the lab and protecting researchers.

C. Energy-efficient ventilation strategies

Research facilities consume significant energy due to the high ventilation requirements. Implementing energy-efficient ventilation strategies can help reduce energy consumption and operational costs while maintaining appropriate air quality. These strategies may include demand-controlled ventilation, variable air volume systems, and the use of energy recovery technologies to reclaim heat or coolness from the exhaust air.

Temperature and Humidity Control

A. Importance of precise temperature control

Accurate temperature control is crucial for research facilities, as many experiments are temperature-sensitive. HVAC systems must be capable of maintaining precise and stable temperature conditions within defined tolerances. Fluctuations in temperature can negatively impact research outcomes, compromise the integrity of samples, and affect the performance of equipment.

B. Humidity control for sensitive research processes

Humidity control is equally important, especially in research involving biological materials, electronic components, or materials sensitive to moisture. Controlling humidity prevents condensation, mold growth, and the degradation of samples or materials. Specialized humidification and dehumidification systems are employed to maintain specific humidity levels required for different research activities.

C. Heat load calculations and system capacity

Accurate heat load calculations are essential to determine the HVAC system’s capacity required to maintain desired temperature conditions. Research facilities generate various heat sources, such as lighting, equipment, and occupants, which need to be considered during the design phase. Oversized or undersized HVAC systems can lead to inefficiencies, poor temperature control, and increased energy consumption.

Filtration and Contaminant Control

A. Types of filters for research facility HVAC systems

Research facilities require effective filtration systems to control airborne contaminants and particulate matter. HEPA filters are commonly used to capture microscopic particles, including dust, allergens, and potentially hazardous substances. Activated carbon filters are used to remove odors and volatile organic compounds (VOCs). Understanding the specific filtration needs and selecting appropriate filters ensures the desired level of air quality in the facility.

B. Controlling airborne contaminants and particulate matter

Research activities can generate airborne contaminants, including dust, biological particles, and chemical fumes. HVAC systems in research facilities must effectively capture and control these contaminants to maintain a safe and clean environment. By using appropriate filtration, air distribution, and containment strategies, the HVAC system can help minimize the spread of contaminants and protect researchers.

C. Ultra-clean environments and HEPA filtration

Some research activities require ultra-clean environments with extremely low levels of airborne particles. Cleanrooms and controlled environments utilize HEPA filtration systems to achieve the desired cleanliness levels. HEPA filters can capture particles as small as 0.3 microns with high efficiency, creating a controlled environment free from contamination.

Energy Efficiency in Research Facility HVAC

A. Energy-saving strategies and equipment selection

Energy efficiency is a critical consideration in research facility HVAC systems due to their high energy consumption. Implementing energy-saving strategies, such as efficient equipment selection, variable speed drives, and optimized control algorithms, can significantly reduce energy usage without compromising performance. Energy-efficient HVAC equipment, including high-efficiency chillers, air handlers, and motors, should be considered during the design and renovation of research facilities.

B. Building automation and controls

Building automation systems and advanced controls provide enhanced monitoring and optimization capabilities for research facility HVAC systems. These systems enable centralized control, scheduling, and data analysis, allowing facility managers to monitor and adjust HVAC operations based on occupancy, activities, and specific research requirements. Smart sensors, occupancy detectors, and data analytics can further optimize energy usage and maintain optimal conditions.

C. Heat recovery systems and energy management

Heat recovery systems can significantly improve HVAC system energy efficiency in research facilities. These systems capture and reuse waste heat generated by HVAC equipment, laboratory processes, or other sources to preheat or precool incoming air or water. By utilizing heat recovery systems, energy consumption can be reduced, and the overall sustainability of the facility can be improved. Additionally, implementing effective energy management practices, such as regular maintenance, performance monitoring, and energy audits, helps identify areas for improvement and optimize energy usage.

Compliance and Safety Considerations

A. Regulatory standards and guidelines

Research facilities must comply with various regulations, standards, and guidelines concerning safety, air quality, and environmental protection. These can include local building codes, Occupational Safety and Health Administration (OSHA) regulations, National Fire Protection Association (NFPA) guidelines, and specific industry standards. HVAC systems must be designed, installed, and maintained in accordance with these requirements to ensure the safety of occupants and compliance with the law.

B. Chemical storage and ventilation requirements

Research facilities often handle hazardous chemicals and materials that require proper storage and ventilation. Chemical storage areas must be adequately ventilated to prevent the accumulation of toxic fumes and ensure the safety of researchers. HVAC systems should incorporate dedicated exhaust systems or separate ventilation zones for chemical storage areas, following established guidelines and best practices.

C. Emergency shutdown and alarm systems

To ensure the safety of occupants and protect valuable research, research facilities require emergency shutdown and alarm systems. HVAC systems should be integrated with these systems to respond to emergency situations promptly. For example, in the event of a fire alarm, the HVAC system can be automatically shut down or adjusted to prevent the spread of smoke or toxic fumes. Collaboration between HVAC professionals and fire protection experts is crucial to designing a comprehensive emergency response system.

Maintenance and Sustainability

A. Regular HVAC system maintenance

Regular maintenance is essential for the optimal performance and longevity of HVAC systems in research facilities. Scheduled inspections, filter replacements, and cleaning ensure that the systems operate efficiently and effectively. Maintenance activities also provide opportunities to identify and address potential issues before they become major problems, minimizing downtime and maintaining the desired environmental conditions.

B. Green initiatives and sustainable practices

Research facilities are increasingly adopting sustainable practices and green initiatives to reduce their environmental impact. HVAC systems can contribute to these efforts by implementing energy-saving measures, promoting the use of renewable energy sources, and adopting sustainable design principles. Incorporating energy-efficient equipment, optimizing system controls, and minimizing waste generation are some of the ways HVAC systems can support sustainability goals.

C. Continuous monitoring and optimization

Continuous monitoring and optimization of HVAC systems are essential to identify areas for improvement and ensure ongoing energy efficiency. Utilizing building automation systems, sensors, and data analytics, facility managers can monitor system performance, analyze energy usage patterns, and identify opportunities for optimization. Regular commissioning and retro-commissioning processes help fine-tune the HVAC systems to achieve optimal performance and energy efficiency.

Future Trends in HVAC for Research Facilities

A. Integration of smart technologies and IoT

The integration of smart technologies and the Internet of Things (IoT) is transforming the HVAC industry. Research facilities can benefit from these advancements by implementing smart sensors, predictive analytics, and remote monitoring capabilities. HVAC systems can be intelligently controlled and optimized, allowing for better energy management, improved performance, and proactive maintenance.

B. Advanced air purification and disinfection systems

The ongoing COVID-19 pandemic has emphasized the importance of indoor air quality and the need for advanced air purification and disinfection systems. Research facilities can explore the integration of technologies such as UV-C germicidal irradiation, photocatalytic oxidation, and plasma air purification to enhance indoor air quality and ensure a safe research environment.

C. Energy recovery and renewable energy solutions

To achieve greater sustainability, research facilities can embrace energy recovery and renewable energy solutions. Heat recovery systems, such as heat pumps or energy recovery ventilators, can capture waste heat and repurpose it for heating or cooling. Integration of renewable energy sources, such as solar panels or geothermal systems, can further reduce reliance on traditional energy sources and decrease the carbon footprint of research facilities.

Conclusion

Research facilities have unique HVAC requirements due to the complex nature of scientific research, the presence of hazardous materials, and the need for precise environmental control. Temperature and humidity control, ventilation for indoor air quality, contaminant control, and filtration are critical aspects of HVAC systems in these settings.

Proper HVAC design is paramount to ensuring the safety, comfort, and integrity of research activities. From maintaining stable temperature and humidity conditions to controlling contaminants and providing adequate ventilation, a well-designed HVAC system supports accurate research outcomes, protects researchers, and safeguards sensitive equipment and samples.

Research facilities should stay abreast of advancements and best practices in HVAC technology to optimize energy efficiency, improve indoor air quality, and enhance sustainability. By integrating smart technologies, advanced filtration systems, energy recovery solutions, and embracing sustainable practices, research facilities can create safer, more comfortable, and environmentally friendly environments for scientific research.

In conclusion, HVAC systems play a vital role in research facilities, providing the necessary environmental control, ventilation, and safety measures required for accurate and safe scientific investigations. Understanding the unique HVAC requirements in research settings, including temperature and humidity control, ventilation systems, filtration, and energy efficiency, is essential for designing and maintaining effective HVAC systems. By embracing advancements in technology and incorporating sustainable practices, research facilities can create optimal environments that support research integrity, researcher well-being, and the advancement of scientific knowledge.

Comments are closed.