GDS Design for Enhanced Efficiency in Industrial Solutions

In the dynamic landscape of industrial solutions, the design and management of Gas Distribution Systems (GDS) play a pivotal role in ensuring operational efficiency.

This blog delves into the intricacies of GDS design, exploring how a well-crafted design can significantly enhance efficiency across various industrial sectors.

1. The Foundation of Efficient Industrial Operations: GDS Design

At the core of many industrial processes lies the intricate network of Gas Distribution Systems. A well-designed GDS ensures the smooth and reliable distribution of gases essential for various operations. From manufacturing plants to research facilities, the efficiency of these systems directly influences overall industrial productivity.

An optimal GDS design not only ensures the timely and accurate delivery of gases but also contributes to safety, cost-effectiveness, and environmental sustainability.

2. Precision Planning: The Key to Effective GDS Design

Engineers must meticulously analyze the specific requirements of the industrial site, considering factors such as gas types, flow rates, pressure levels, and safety protocols. The goal is to create a design that not only meets current operational needs but also allows for scalability and adaptability to future changes.

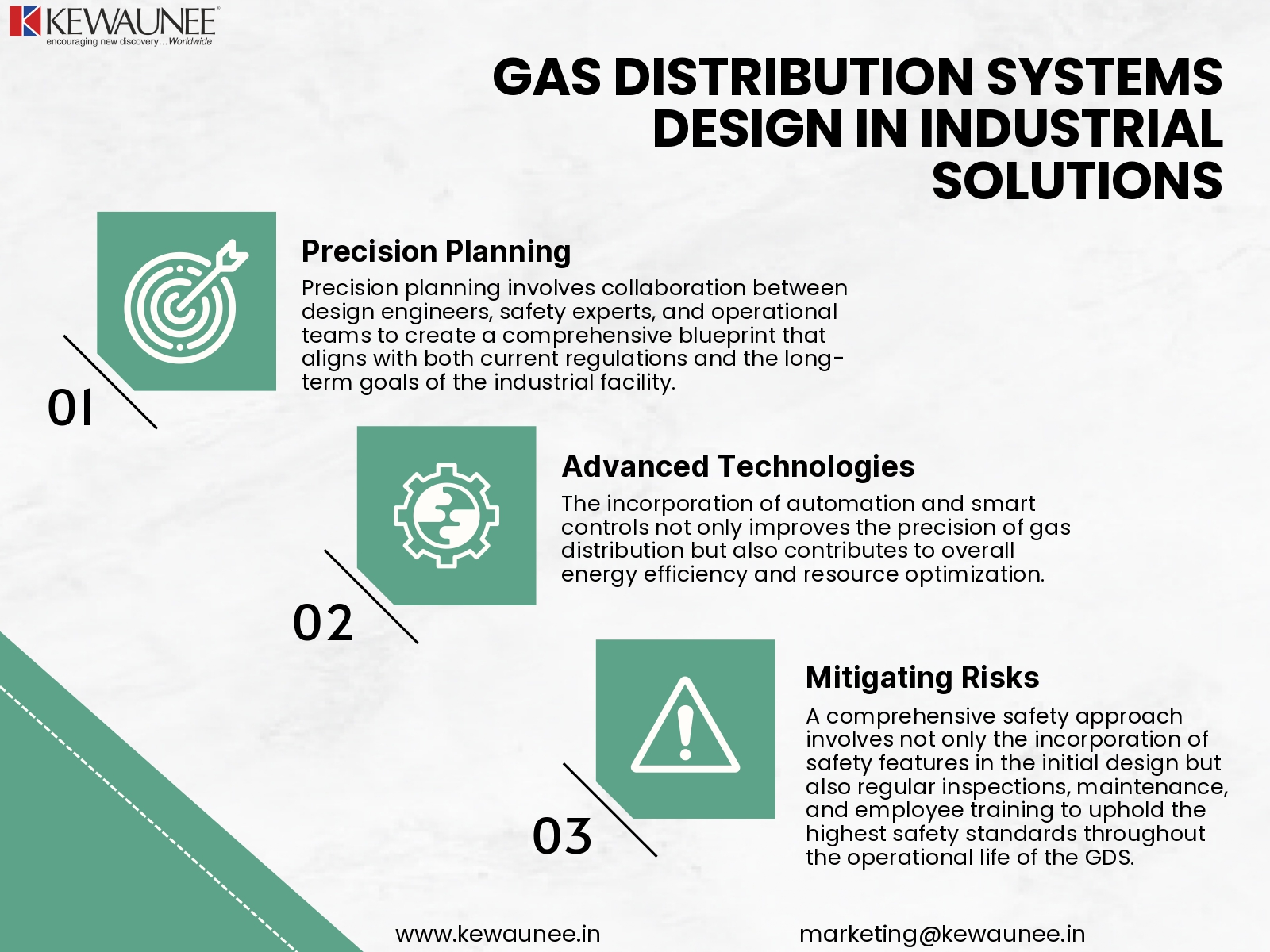

Precision planning involves collaboration between design engineers, safety experts, and operational teams to create a comprehensive blueprint that aligns with both current regulations and the long-term goals of the industrial facility.

3. Integration of Advanced Technologies in GDS Design

Advancements in technology have a profound impact on GDS design, ushering in an era of smart and efficient systems. These technological enhancements offer real-time insights into the performance of the system, allowing for proactive adjustments and preventive maintenance.

The incorporation of automation and smart controls not only improves the precision of gas distribution but also contributes to overall energy efficiency and resource optimization.

4. Safety Measures in GDS Design: Mitigating Risks

Ensuring the safety of industrial operations is paramount in GDS design including pressure relief systems, emergency shut-off mechanisms, and compliance with industry safety standards. The goal is to mitigate risks associated with gas distribution, safeguarding both personnel and equipment.

A comprehensive safety approach involves not only the incorporation of safety features in the initial design but also regular inspections, maintenance, and employee training to uphold the highest safety standards throughout the operational life of the GDS.

Summary

In conclusion, the design of Gas Distribution Systems stands as a linchpin in the efficient functioning of industrial processes. From precision planning to the integration of advanced technologies and a steadfast commitment to safety, this blog underscores the multifaceted aspects that contribute to enhanced efficiency in GDS design.

As industries evolve, the role of GDS design becomes increasingly critical in shaping industrial solutions that are not only productive but also sustainable and safe.

Comments are closed.