Revolutionizing Chemical Plant Construction

Chemical plant construction stands at the crossroads of innovation, safety, and efficiency. This blog serves as a comprehensive guide to the transformative processes and methodologies revolutionizing the landscape of chemical plant construction.

From design considerations to advanced construction techniques, each section unveils a key aspect of this dynamic and evolving industry.

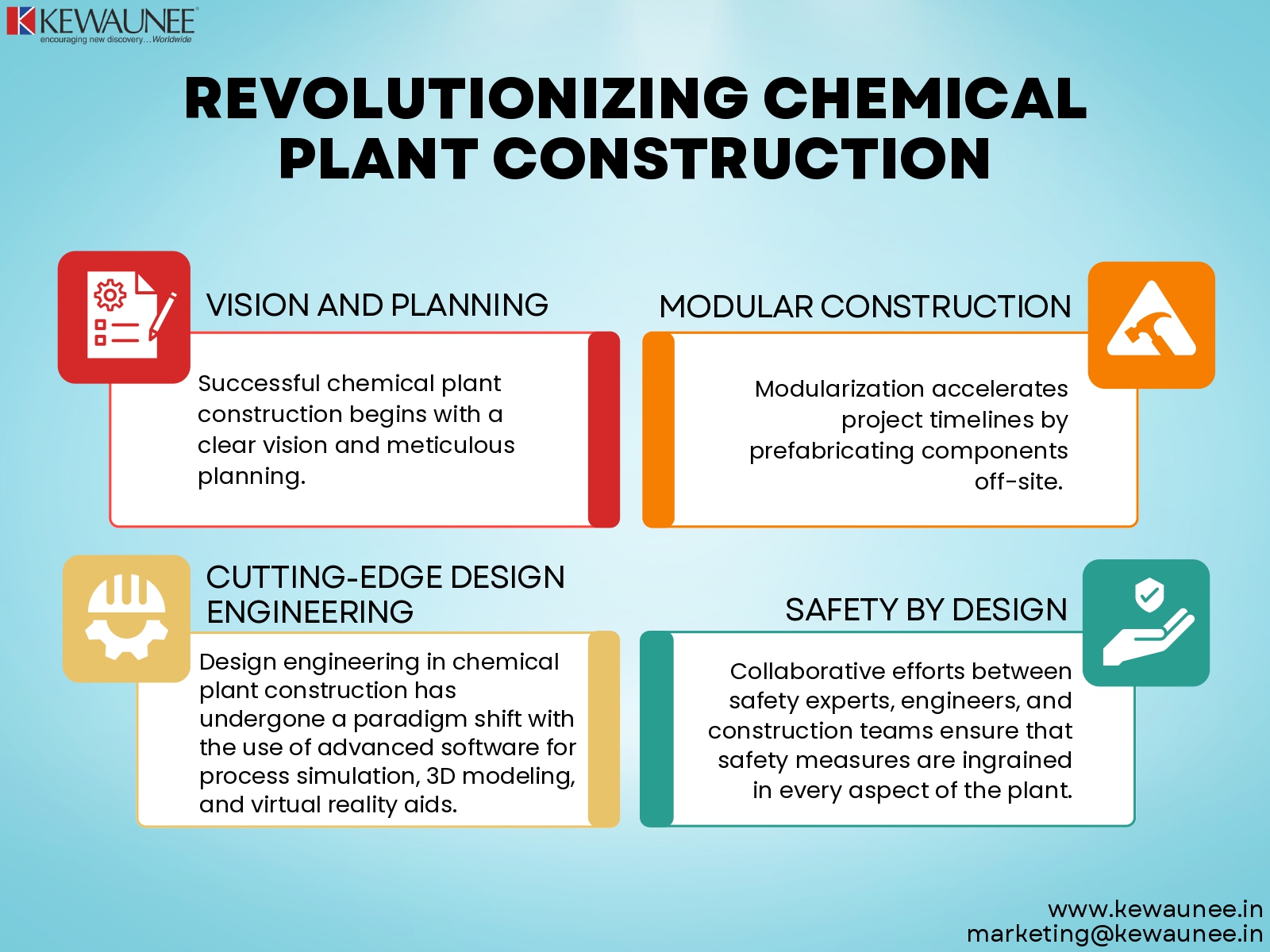

1. Vision and Planning: The Foundation of Success

Successful chemical plant construction begins with a clear vision and meticulous planning. Understanding the specific needs of chemical processes, regulatory compliance, and safety standards forms the foundation for a well-defined project plan.

In the planning phase, collaboration among architects, engineers, and project managers is paramount. Establishing a comprehensive roadmap that aligns with project goals ensures a smooth transition from concept to execution.

2. Cutting-Edge Design Engineering: Beyond Conventional Approaches

Design engineering in chemical plant construction has undergone a paradigm shift. The use of advanced software for process simulation, 3D modeling, and virtual reality aids in creating a detailed and accurate representation of the plant before construction begins.

Design considerations extend beyond structural elements to incorporate safety features, environmental impact assessments, and energy efficiency. The integration of innovative design engineering ensures that chemical plants are not only functional but also optimized for performance and sustainability.

3. Modular Construction: Streamlining Project Timelines

Modular construction is redefining the pace of chemical plant construction. Modularization accelerates project timelines by prefabricating components off-site. Modular units, including process equipment and piping systems, are manufactured in controlled environments, ensuring quality control and reducing on-site construction time.

The benefits of modular construction include cost savings, minimized disruptions to existing operations, and increased safety through reduced on-site activities. Embracing modularization is a strategic move toward achieving efficient and timely project delivery.

4. Safety by Design: Mitigating Risks from the Ground Up

Safety is a non-negotiable aspect of chemical plant construction. Collaborative efforts between safety experts, engineers, and construction teams ensure that safety measures are ingrained in every aspect of the plant.

Innovations such as inherently safer design principles, process automation, and advanced safety instrumentation contribute to creating a safer working environment. Prioritizing safety by design minimizes the potential for accidents and enhances the overall resilience of chemical plants.

Summary

Revolutionizing chemical plant construction involves a holistic approach, encompassing visionary planning, cutting-edge design engineering, modular construction techniques, and an unwavering commitment to safety.

This comprehensive guide sheds light on the dynamic landscape of chemical plant construction, showcasing the strategies and innovations that propel the industry forward. As the demand for chemical products continues to rise, embracing these transformative practices ensures that chemical plants are not just structures but efficient, safe, and sustainable hubs of industrial excellence.

Comments are closed.