Advancements in Fume Hood Technologies for Lab Safety and Efficiency

Fume hoods are essential equipment in laboratories that handle hazardous chemicals and materials. They provide a safe working environment for laboratory workers by containing and filtering out harmful fumes and gases.

Fume hoods not only protect laboratory workers but also ensure the accuracy and reliability of experiments by preventing contamination.

In recent years, innovative technologies have been developed to improve the safety and efficiency of fume hoods. These technologies not only enhance laboratory safety but also reduce energy consumption and operational costs.

This blog will provide an overview of traditional fume hoods and their limitations, innovative technologies in fume hoods, their benefits, and considerations for implementing them in laboratories. We will also discuss the emerging trends in fume hood design and operation.

Traditional Fume Hoods: Limitations and Challenges

Traditional fume hoods are designed to remove fumes and gases from the laboratory environment by pulling them through a duct system and expelling them outside or through a filter. While they have been a standard in laboratory safety for many years, traditional fume hoods have several limitations and challenges.

One of the main limitations is their energy consumption. Traditional fume hoods use a large amount of energy to draw air through the hood to maintain the necessary airflow. Additionally, traditional fume hoods do not have the ability to adjust the airflow based on the needs of the experiment, leading to unnecessary energy waste.

Another limitation is that traditional fume hoods require regular maintenance to ensure their effectiveness. This includes regular inspections, filter changes, and duct cleaning. Neglecting maintenance can lead to contaminated air being released into the laboratory environment.

Innovative Technologies in Fume Hoods

Innovative technologies have been developed to address the limitations and challenges of traditional fume hoods. These technologies focus on improving fume hood design and operation, making them more energy-efficient and user-friendly.

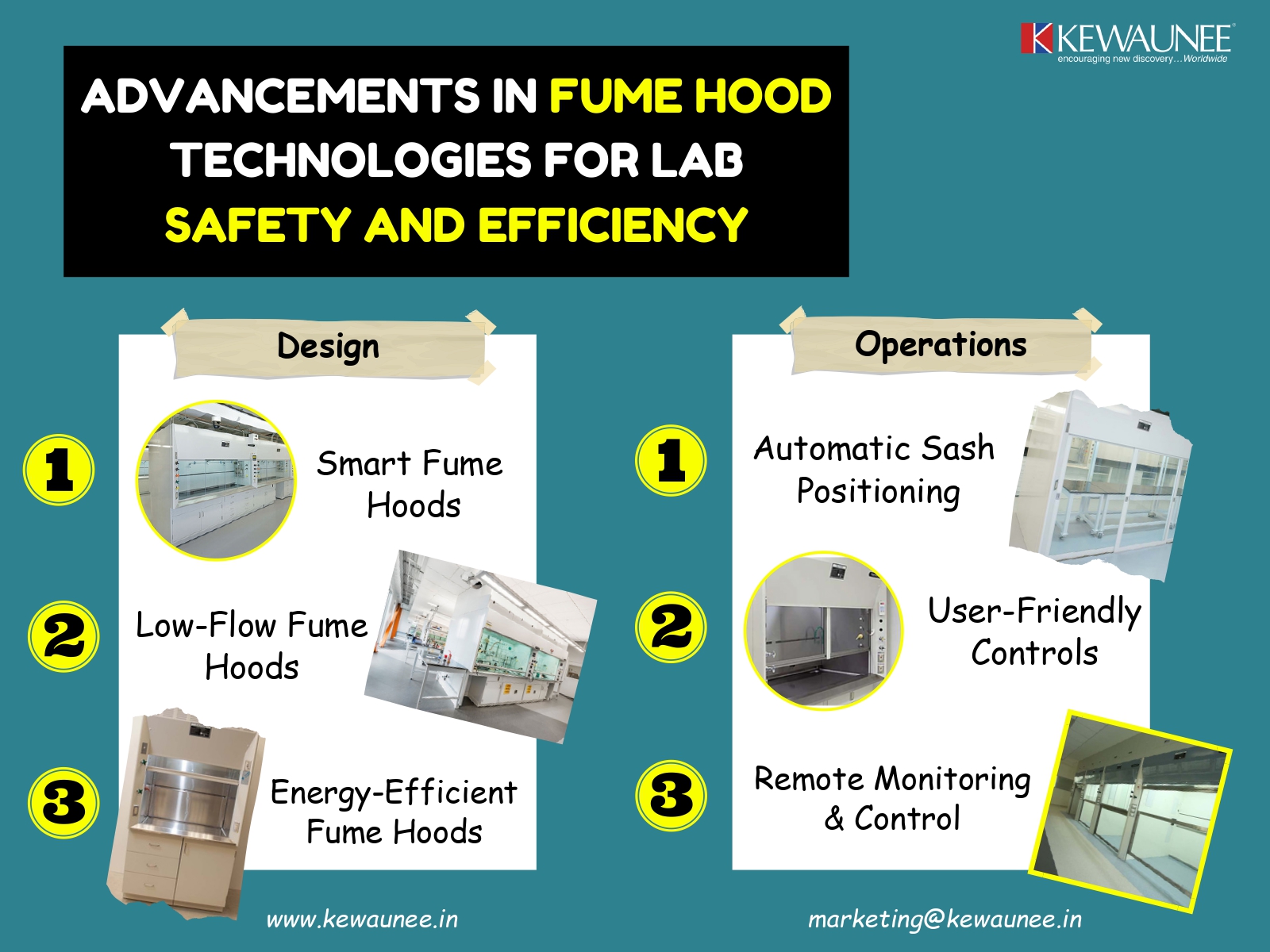

Advancements in fume hood design

- Smart Fume Hoods – Smart fume hoods use sensors to detect the presence of chemicals and adjust the airflow accordingly. This reduces energy consumption by only drawing the necessary amount of air to maintain a safe working environment.

- Low-Flow Fume Hoods – Low-flow fume hoods use less energy by reducing the amount of air drawn through the hood. This is achieved by using a baffle system that directs air to where it is needed most.

- Energy-Efficient Fume Hoods – Energy-efficient fume hoods are designed to use less energy while still providing a safe working environment. These hoods use a combination of low-flow technology, variable airflow controls, and efficient motor systems to reduce energy consumption.

Advancements in fume hood operation

- Automatic Sash Positioning – Automatic sash positioning systems adjust the sash height based on the location of the worker, ensuring the airflow is directed to the source of the fumes, reducing energy consumption, and increasing safety.

- User-Friendly Controls – User-friendly controls make it easier for laboratory workers to adjust the airflow and lighting in the fume hood. This makes the fume hood more efficient to use and minimizes the risk of user error.

- Remote Monitoring and Control – Remote monitoring and control systems allow laboratory managers to monitor fume hood performance and adjust remotely, increasing safety and reducing energy consumption.

Benefits of Innovative Technologies in Fume Hoods

Implementing innovative technologies in fume hoods provides several benefits for laboratory safety, efficiency, and the environment. These benefits include:

- Improved Safety for Laboratory Workers – Innovative technologies reduce the risk of exposure to hazardous chemicals and gases, providing a safer working environment for laboratory workers.

- Increased Energy Efficiency and Cost Savings – Innovative fume hood technologies reduce energy consumption and operational costs, resulting in cost savings for laboratory managers.

- Reduced Environmental Impact – Innovative fume hood technologies reduce energy consumption, resulting in reduced greenhouse gas emissions and lower carbon footprint. Additionally, some technologies use filters that can be recycled, reducing waste.

- Improved Laboratory Efficiency and Productivity – Innovative fume hood technologies increase laboratory efficiency by improving the accuracy and reliability of experiments. They also reduce the time and effort required for maintenance and servicing, allowing laboratory workers to focus on their research.

Considerations for Implementing Innovative Technologies in Fume Hoods

While innovative technologies in fume hoods provide significant benefits, there are several considerations for laboratory managers to keep in mind when implementing them. These considerations include:

- Upfront Costs and Return on Investment – Innovative fume hood technologies can have a higher upfront cost compared to traditional fume hoods. However, laboratory managers should consider the long-term cost savings resulting from reduced energy consumption and operational costs.

- Compatibility with Existing Laboratory Equipment – Laboratory managers should ensure that innovative fume hood technologies are compatible with existing laboratory equipment, including HVAC systems.

- Training Requirements for Laboratory Staff – Laboratory workers may require additional training to operate and maintain innovative fume hood technologies effectively. Laboratory managers should plan for this training in their implementation strategy.

- Maintenance and Servicing Considerations – While innovative fume hood technologies may require less maintenance than traditional fume hoods, laboratory managers should still plan for regular maintenance and servicing to ensure optimal performance.

Future of Fume Hoods: Emerging Technologies and Trends

The future of fume hoods is focused on improving safety, efficiency, and sustainability. Emerging technologies include:

- Integrating fume hoods with building automation systems to improve energy efficiency and control.

- Using artificial intelligence and machine learning to optimize fume hood airflow based on laboratory conditions and experiment requirements.

- Incorporating sustainable materials into fume hood construction, reducing environmental impact.

Conclusion

Innovative technologies in fume hoods provide significant benefits for laboratory safety, efficiency, and sustainability. While they may have a higher upfront cost, the long-term cost savings resulting from reduced energy consumption and operational costs make them a worthwhile investment for laboratory managers. Laboratory managers should consider the compatibility with existing laboratory equipment, training requirements for laboratory staff, and maintenance and servicing considerations when implementing these technologies. With the continued development of emerging technologies, the future of fume hoods is focused on improving safety, efficiency, and sustainability, ensuring the protection of laboratory workers and the environment.

Comments are closed.