The Future of Manufacturing Industrial IoT

Industrial Internet of Things (IIoT) is a powerful convergence of machinery and digital technology. The IIoT is revolutionizing manufacturing by providing real-time data, predictive analytics, and automation that enhance efficiency, reduce downtime, and improve product quality.

In this blog, we’ll delve into the future of Industrial IoT and its transformative impact on manufacturing.

1. Introduction to Industrial IoT

The Industrial Internet of Things refers to the network of interconnected devices, sensors, and machinery within an industrial setting. These devices are equipped with sensors and software that enable them to collect and exchange data. This data can be harnessed for various purposes, including monitoring, analysis, and automation.

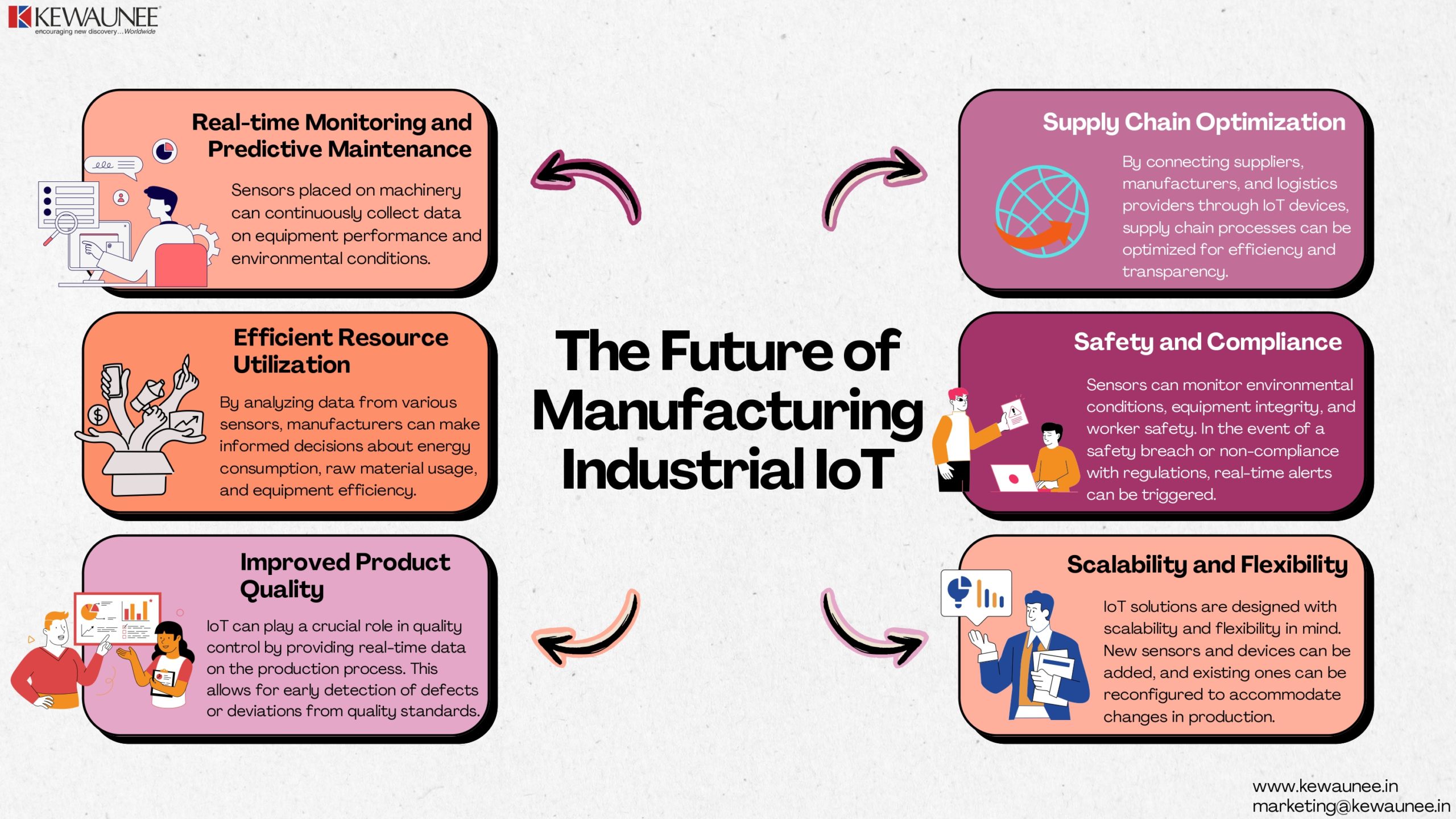

2. Real-time Monitoring and Predictive Maintenance

One of the significant advantages of IIoT is real-time monitoring. Sensors placed on machinery can continuously collect data on equipment performance and environmental conditions. This data is transmitted in real time to central systems where it can be analyzed.

3. Efficient Resource Utilization

Efficient resource utilization is a critical factor in manufacturing. IIoT enables manufacturers to optimize resource usage. By analyzing data from various sensors, manufacturers can make informed decisions about energy consumption, raw material usage, and equipment efficiency.

4. Improved Product Quality

In manufacturing, ensuring product quality is paramount. IIoT can play a crucial role in quality control by providing real-time data on the production process. This allows for early detection of defects or deviations from quality standards.

5. Supply Chain Optimization

The IIoT isn’t limited to the factory floor. It extends to the entire supply chain. By connecting suppliers, manufacturers, and logistics providers through IoT devices, supply chain processes can be optimized for efficiency and transparency.

6. Safety and Compliance

Safety is a top priority in manufacturing, and IIoT can enhance it. Sensors can monitor environmental conditions, equipment integrity, and worker safety. In the event of a safety breach or non-compliance with regulations, real-time alerts can be triggered.

7. Scalability and Flexibility

Manufacturers often need to adapt quickly to changing market demands. IIoT solutions are designed with scalability and flexibility in mind. New sensors and devices can be added, and existing ones can be reconfigured to accommodate changes in production.

8. Challenges and Considerations

While the benefits of IIoT are undeniable, there are challenges to overcome. Security is a major concern, as interconnected devices can be vulnerable to cyberattacks. Data privacy is another issue, as sensitive production data must be protected.

9. The Future Landscape

The future of Industrial IoT holds exciting possibilities. As technology continues to advance, we can expect even more sophisticated sensors, improved connectivity, and AI-driven analytics. This will lead to more intelligent and autonomous manufacturing processes.

Summary

The Industrial Internet of Things is at the forefront of manufacturing transformation. Its ability to provide real-time data, predictive analytics, and automation is reshaping the industry. As we look ahead, the IIoT will continue to evolve, bringing new opportunities and challenges to the world of manufacturing. Embracing this technology will be key to staying competitive and innovative in an ever-changing landscape.

Comments are closed.