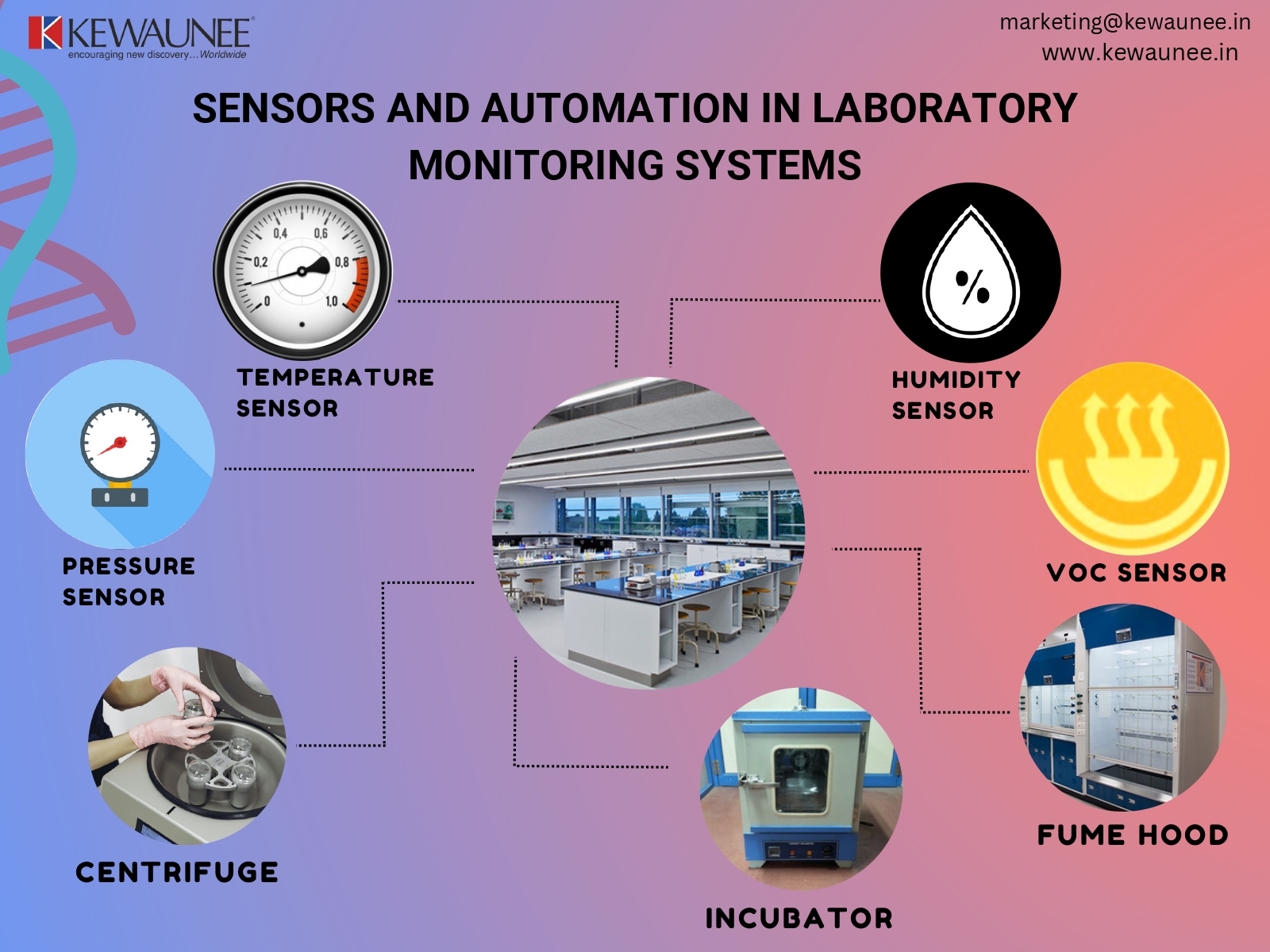

Sensors and Automation in Laboratory Monitoring Systems

Laboratory monitoring systems are designed to collect, analyze and record data in a laboratory setting. These systems are used to ensure the safety and accuracy of experiments, as well as the quality of the results obtained.

The purpose of monitoring systems in laboratory settings is to provide real-time data to researchers and laboratory staff, allowing them to make informed decisions and take corrective actions if necessary. This can include monitoring environmental conditions, such as temperature and humidity, as well as monitoring the progress of experiments and the quality of the results.

Sensors and automation play a critical role in modern laboratory monitoring systems. Sensors are used to collect data, while automation is used to analyze and process that data. Together, sensors and automation allow for real-time monitoring and control of laboratory conditions and processes, increasing efficiency and accuracy in the laboratory.

Types of Sensors

Sensors come in a variety of types, each with its own specific application in laboratory monitoring systems. These can include temperature sensors, humidity sensors, pressure sensors, pH sensors, and more.

Temperature sensors, for example, can be used to monitor the temperature of a laboratory or specific equipment, while pH sensors can be used to measure the acidity or alkalinity of a solution. These sensors can be integrated into laboratory equipment, such as centrifuges, fume hoods, or incubators, or they can be used as stand-alone devices.

The role of sensors in laboratory monitoring systems is to collect data on various conditions and parameters in the laboratory. This data is then used to make informed decisions and take corrective actions if necessary. Sensors can also be used to trigger alarms or shut down equipment in the event of an abnormal condition.

Automation in Monitoring Systems

Automation in laboratory monitoring systems allows for real-time data analysis and control of laboratory conditions and processes. This can include automatic adjustments to temperature, humidity, or other environmental conditions, as well as automatic shutdown of equipment in the event of an abnormal condition.

Automation can also be used in laboratory monitoring systems to control the progress of experiments, such as automatically adjusting the speed of a centrifuge, lowering a fume hood sash, or changing the temperature of an incubator.

The role of automation in laboratory monitoring systems is to increase the efficiency and accuracy of laboratory operations. By automating data analysis and control of laboratory conditions and processes, automation allows for real-time monitoring and control of laboratory conditions, reducing the risk of human error and increasing the reliability of results.

Integration of Sensors and Automation

Integrating sensors and automation in laboratory monitoring systems involves combining the data collected by sensors with the control capabilities of automation. This can include using sensor data to automatically adjust laboratory conditions, or using automation to control the progress of experiments based on sensor data.

Challenges and considerations in integrating sensors and automation in laboratory monitoring systems include ensuring compatibility between different types of sensors and automation systems, and properly configuring the systems to work together seamlessly. It is also important to consider the scalability of the system, as laboratory needs and requirements may change over time.

Tips for successful integration of sensors and automation in laboratory monitoring systems include proper planning and testing, selecting compatible systems and technologies, and regularly reviewing and updating the system to ensure it is meeting the needs of the laboratory.

Conclusion

In conclusion, sensors and automation play a critical role in modern laboratory monitoring systems, allowing for real-time monitoring and control of laboratory conditions and processes, increasing efficiency and accuracy in the laboratory.

Proper integration of sensors and automation is crucial for ensuring the effectiveness of laboratory monitoring systems, and should be considered during the design and implementation stages.

Laboratory managers and technicians should consider incorporating sensors and automation in their laboratory monitoring systems to improve the safety, efficiency, and accuracy of their laboratory operations.

Comments are closed.