Laboratory Contamination: Identifying and Mitigating Sources

Laboratory results serve as the foundation for scientific research, medical diagnoses, and quality control in various industries. Accurate and reliable data is crucial for making informed decisions, ensuring patient safety, and advancing scientific knowledge.

Laboratory contamination refers to the unintended presence of foreign substances or microorganisms that can compromise the integrity and accuracy of experimental or diagnostic results.

Contamination can arise from various sources, including airborne particles, sample cross-contamination, personnel-related factors, and equipment or instrument contamination. Identifying and mitigating these sources are essential to maintain the reliability of laboratory results.

Understanding Laboratory Contamination

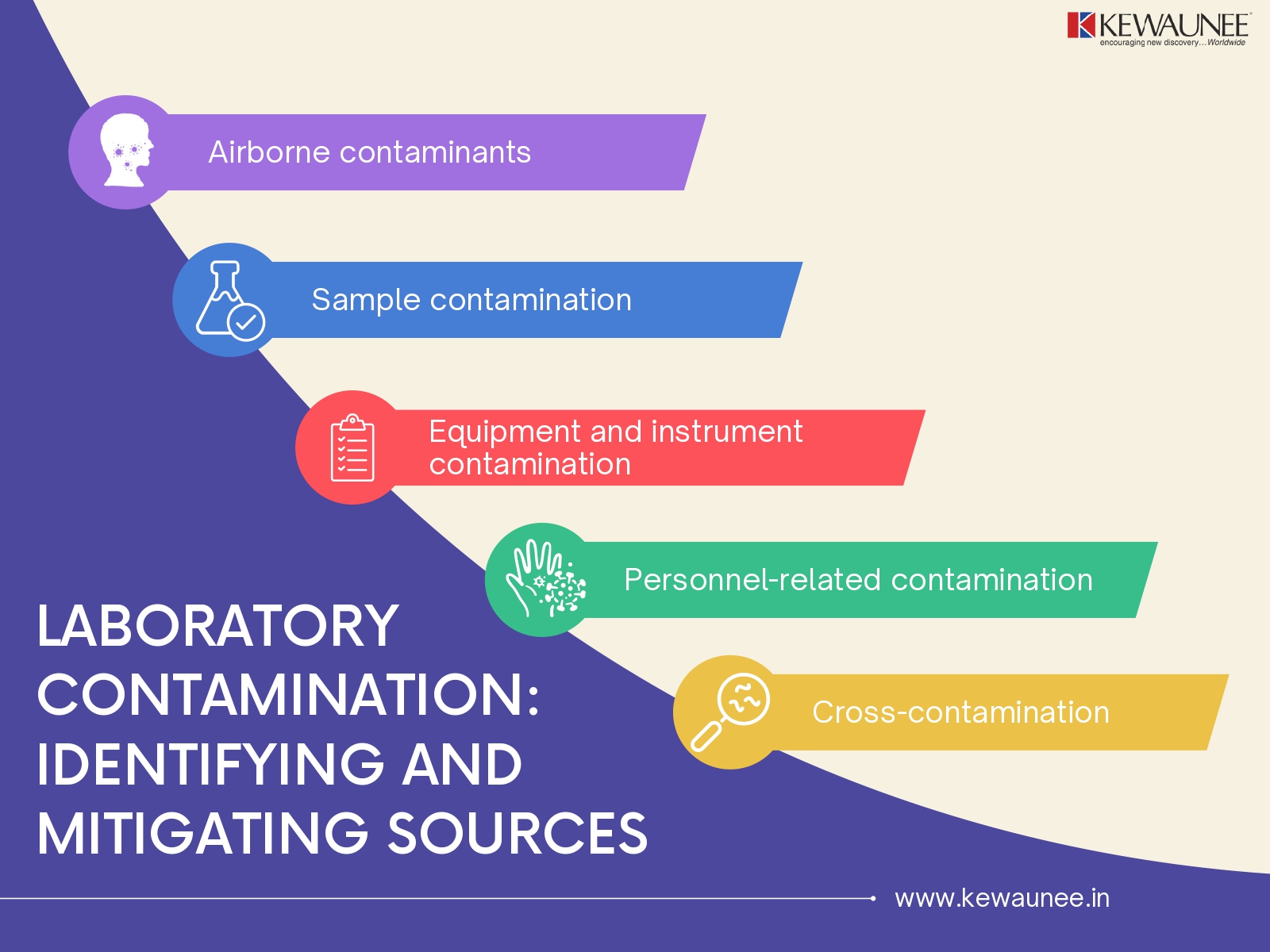

Laboratory contamination encompasses the introduction of unwanted materials or substances that can alter the composition or integrity of samples, reagents, or experimental setups. It can be classified into several types, including airborne contaminants, sample contamination, equipment and instrument contamination, personnel-related contamination, and cross-contamination.

- Airborne contaminants: These include dust particles, aerosols, microorganisms, and chemical vapors present in the laboratory environment, which can settle on surfaces or directly interact with samples.

- Sample contamination: Occurs when external substances, such as microorganisms, chemicals, or particles, inadvertently enter or contaminate the sample, leading to false results or experimental failure.

- Equipment and instrument contamination: When laboratory equipment or instruments are not properly cleaned, calibrated, or maintained, they can introduce contaminants that affect the accuracy and reliability of experimental outcomes.

- Personnel-related contamination: Human activities, such as improper hand hygiene, shedding of skin cells, or sneezing, can introduce microorganisms or particles into the laboratory environment, thereby contaminating samples or equipment.

- Cross-contamination: The transfer of contaminants between samples, reagents, or surfaces, leading to the contamination of otherwise uncontaminated materials.

Identifying Sources of Laboratory Contamination

A. Contamination detection methods and tools

To identify potential contamination sources, laboratories employ various detection methods and tools that enable accurate assessment and monitoring.

- Air monitoring devices: These devices measure airborne particles, microorganisms, or chemical pollutants present in the laboratory environment, providing insights into air quality and contamination risks.

- Surface sampling techniques: Swabbing, contact plates, or adhesive tapes are used to collect samples from surfaces and equipment, allowing for the detection and analysis of microbial or particulate contamination.

- Molecular techniques (e.g., PCR, DNA sequencing): Molecular methods can identify and quantify specific microbial or genetic material in samples, helping determine if contamination has occurred.

B. Routine monitoring and surveillance strategies

Regular monitoring and surveillance strategies are essential to maintain a clean and contamination-free laboratory environment.

- Regular cleaning and maintenance protocols: Laboratories must establish robust protocols for routine cleaning and maintenance of equipment, benches, and work areas to minimize contamination risks.

- Quality control measures: Implementation of quality control measures, such as running positive and negative controls alongside experimental samples, helps detect potential contamination during experimental procedures.

- Environmental monitoring programs: Environmental monitoring involves regularly assessing the laboratory’s air quality, water sources, and surfaces to identify any potential sources of contamination and take corrective actions.

Mitigating Laboratory Contamination

A. Establishing a contamination control plan

Laboratories should develop and implement a contamination control plan to minimize contamination risks and maintain accurate results.

- Proper laboratory layout and workflow optimization: Designing a laboratory layout that separates clean and contaminated areas, minimizes traffic, and ensures efficient workflow can reduce the likelihood of contamination.

- HVAC systems and air filtration: Installing high-quality HVAC systems with appropriate air filtration capabilities helps maintain clean air in the laboratory by minimizing the presence of airborne contaminants.

- Containment measures and controlled access: Implementing physical barriers, such as biosafety cabinets, fume hoods, or restricted access areas, can prevent the spread of contaminants and maintain controlled environments for specific experiments or procedures.

B. Personal hygiene and best practices for laboratory personnel

Laboratory personnel play a critical role in preventing contamination through adherence to proper personal hygiene practices.

- Proper attire and personal protective equipment (PPE): Wearing appropriate laboratory attire, including lab coats, gloves, safety goggles, and masks, helps minimize the transfer of microorganisms or particles from personnel to samples or equipment.

- Hand hygiene and cleanliness protocols: Rigorous handwashing with soap and water, or the use of alcohol-based sanitizers, is crucial to reduce the potential for microbial transfer.

C. Equipment and instrument maintenance and decontamination

Regular maintenance and decontamination of laboratory equipment and instruments are essential to prevent contamination and maintain their accuracy and reliability.

- Regular calibration and cleaning procedures: Following manufacturer guidelines for equipment calibration and implementing regular cleaning protocols helps ensure accurate measurements and reduces the risk of contamination.

- Sterilization and decontamination protocols: Implementing appropriate sterilization and decontamination procedures for reusable equipment, glassware, or instruments is vital to eliminate potential sources of contamination.

Training and Education

- Providing comprehensive training to laboratory personnel is crucial in fostering a culture of contamination control and ensuring adherence to best practices.

- Educating laboratory staff on good laboratory practices, including contamination prevention, proper handling of samples and reagents, and maintaining a clean work environment, enhances overall laboratory performance and minimizes risks.

- Encouraging personnel to actively participate in contamination control efforts, report potential issues, and share knowledge helps create a culture of awareness and responsibility towards maintaining a contamination-free laboratory.

Quality Assurance and Validation

- Implementation of quality control measures, such as running appropriate controls, validation of methods, and data verification, helps ensure the accuracy and reliability of laboratory results.

- Validating laboratory methods and protocols through rigorous testing and evaluation ensures that contamination risks are minimized, and accurate results are consistently obtained.

- Maintaining detailed records of experiments, processes, and potential sources of contamination allows for efficient tracking and identification of any recurring contamination issues, enabling prompt corrective actions.

Emerging Technologies and Best Practices

- Stay updated on emerging technologies, such as improved air filtration systems, advanced sterilization techniques, and automated monitoring systems, that aid in contamination control efforts.

- Automation and robotics can minimize the risk of human error and cross-contamination by reducing manual handling and ensuring precise and controlled experimental procedures.

- Utilizing single-use and disposable materials, such as pipette tips, tubes, and filters, eliminates the need for extensive cleaning and sterilization, reducing the risk of contamination.

- Learn from industry leaders and successful case studies that highlight effective contamination control practices, innovative approaches, and lessons learned from real-world scenarios.

Conclusion

Laboratory contamination can significantly impact the accuracy and reliability of results, potentially leading to erroneous conclusions, compromised experiments, or incorrect diagnoses.

Establishing robust contamination control measures, including routine monitoring, proper hygiene practices, equipment maintenance, and staff training, is crucial for obtaining accurate and reliable laboratory results.

Maintaining a contamination-free laboratory requires ongoing vigilance, regular training, and continuous improvement of protocols and practices. By prioritizing contamination control, laboratories can uphold the highest standards of accuracy and reliability in their results, contributing to advancements in science, healthcare, and various industries.

Comments are closed.