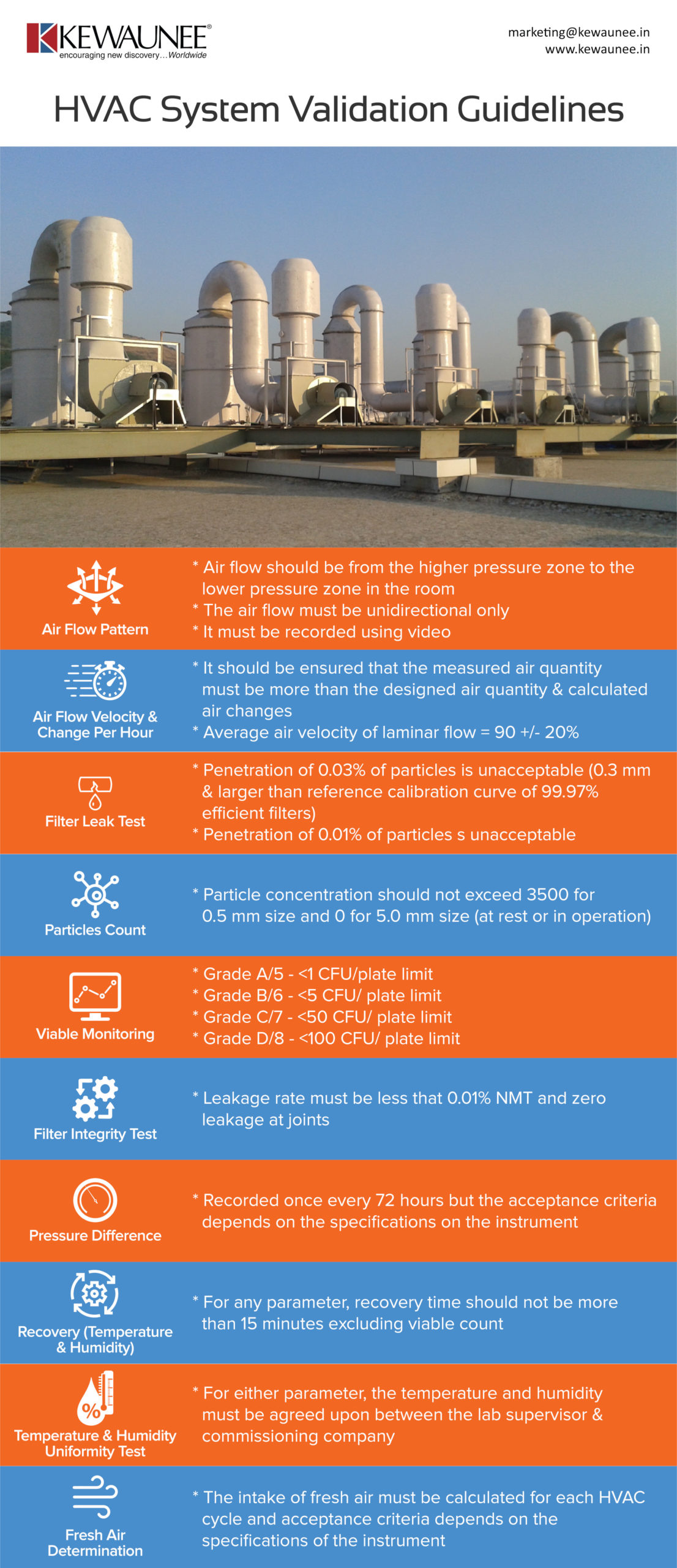

HVAC System Validation Guidelines

Heating, Ventilation, and Air Conditioning (HVAC) is a much-required equipment in any laboratory. It controls how the temperature, humidity, and air flow works within the room. It’s critical to the functioning of any laboratory, especially those that make use of hazardous materials.

In this infographic, we will look at how a HVAC system is validated before installation, and what aspects need to be considered for the same. If you’re looking to commission such devices for your laboratory, you can have a look at our range of products here: https://www.kewaunee.in/ventilated-devices.php

| Tests | Acceptance Criteria |

| Air Flow Pattern |

|

| Air Flow Velocity & Change Per Hour |

|

| Filter Leak Test |

|

| Particles Count |

|

| Viable Monitoring |

|

| Filter Integrity Test |

|

| Pressure Difference |

|

| Recovery (Temperature & Humidity) |

|

| Temperature & Humidity Uniformity Test |

|

| Fresh Air Determination |

|

Source: Pharma Guidelines, n.d.

Comments are closed.