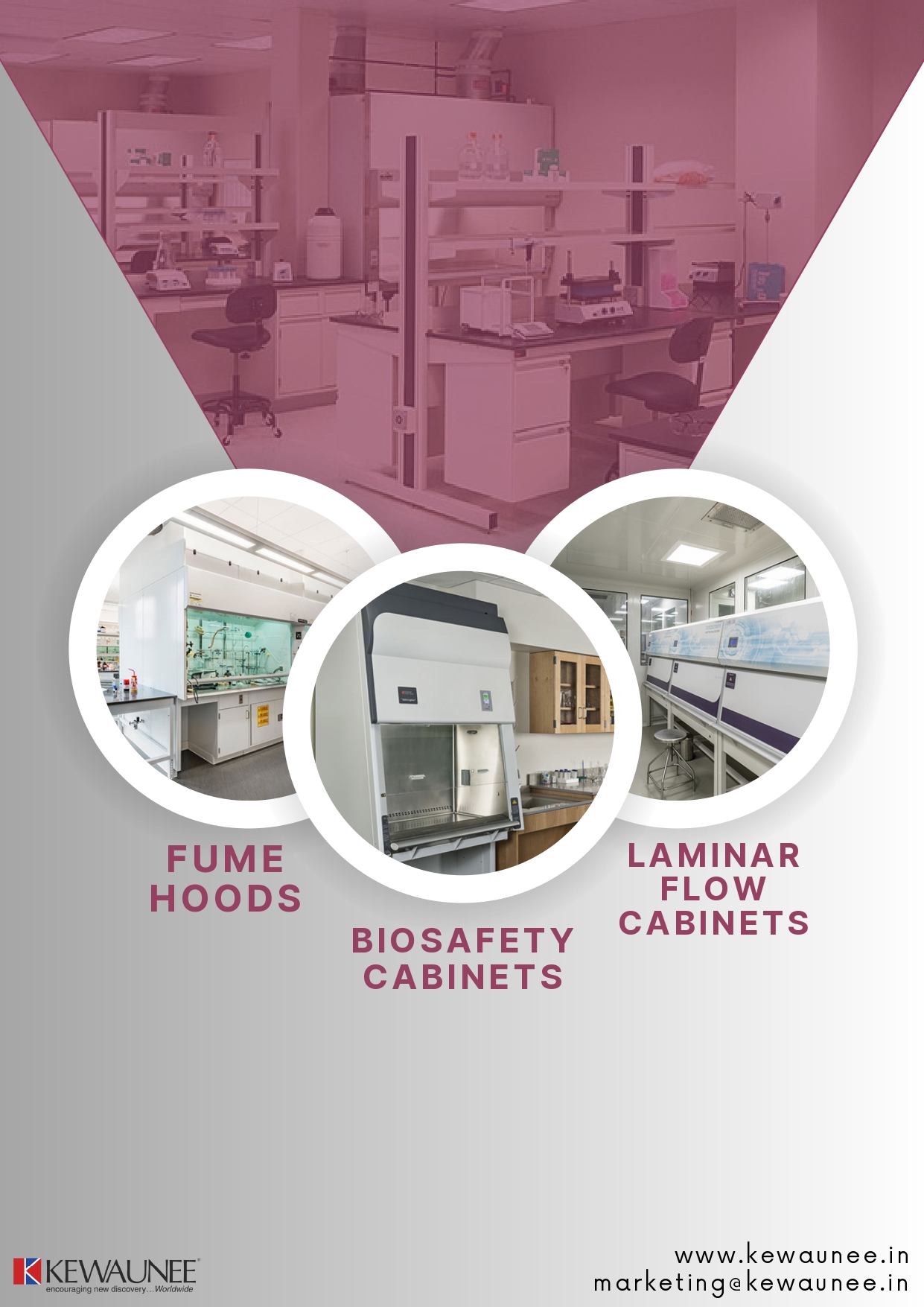

Fume Hoods, Biosafety Cabinets, and Laminar Flow Cabinets

In laboratory environments, proper ventilation plays a critical role in maintaining the health and safety of researchers, as well as preserving the integrity of experiments and samples. Effective ventilation helps control and eliminate hazardous substances, such as chemical fumes, volatile compounds, and biological agents.

It also helps mitigate the risks associated with airborne particles and cross-contamination. By ensuring clean and breathable air, ventilation systems contribute to the overall well-being of laboratory personnel and the quality of scientific research conducted.

Ventilated devices are specifically designed to provide controlled airflow and containment solutions within laboratories. Three common types of ventilated devices are fume hoods, biosafety cabinets, and laminar flow cabinets.

Each of these devices serves a unique purpose and offers distinct features to address specific ventilation needs in the lab environment. Understanding their differences and applications is essential for creating an optimal and safe working environment.

Fume Hoods

Fume hoods are widely used in laboratories to control and remove chemical fumes, gases, and vapors generated during various experimental processes. They create a physical barrier between the operator and the hazardous substances, protecting personnel from potential exposure.

How fume hoods work to protect laboratory personnel

Fume hoods operate on the principle of negative pressure. The hood enclosure captures and contains the hazardous substances, while an exhaust system removes and filters the contaminated air, preventing it from entering the laboratory space.

Types of fume hoods (e.g., ducted, ductless)

Fume hoods are available in two primary types: ducted and ductless. Ducted fume hoods connect to an external exhaust system, expelling the contaminated air outside the building. Ductless fume hoods, also known as recirculating or filtered fume hoods, use filtration systems to remove hazardous substances before recirculating the air back into the laboratory.

Considerations for selecting and using fume hoods

When selecting a fume hood, factors such as the nature of the hazardous materials, the required airflow, and the specific laboratory needs must be considered. Proper usage of fume hoods involves following safety protocols, maintaining adequate airflow, and ensuring regular inspections and maintenance.

Maintenance and safety guidelines for fume hoods

Regular maintenance, including inspections, testing, and cleaning, is crucial for the effective functioning of fume hoods. Safety guidelines encompass proper use of protective equipment, awareness of potential hazards, and adherence to standard operating procedures.

Biosafety Cabinets

Biosafety cabinets (BSCs) are specialized ventilated devices designed to provide both personnel and environmental protection when working with biological agents, such as microorganisms and pathogens. They create a containment barrier that prevents the release of hazardous biological material.

Classifications of biosafety cabinets (e.g., Class I, Class II, Class III)

Biosafety cabinets are classified into three primary classes based on their design and level of protection. Class I cabinets provide personnel protection, Class II cabinets offer personnel and environmental protection, while Class III cabinets provide the highest level of containment for working with highly hazardous agents.

Functions and applications of biosafety cabinets

Biosafety cabinets serve various functions, including preventing the escape of biological agents, maintaining a sterile work environment, and protecting personnel from exposure. They are commonly used in research laboratories, clinical facilities, and pharmaceutical industries.

Key features and components of biosafety cabinets

Biosafety cabinets include features such as HEPA filters, airflow systems, and air curtains to ensure proper containment and filtration. They also consist of work surfaces, gloves, and access ports, allowing researchers to perform tasks safely within the enclosed workspace.

Proper usage, maintenance, and certification of biosafety cabinets

Proper usage of biosafety cabinets involves following standard operating procedures, wearing appropriate personal protective equipment, and disinfecting the workspace. Regular maintenance, certification, and validation of performance are essential to ensure continued safe operation and compliance with regulatory standards.

Laminar Flow Cabinets

Laminar flow cabinets create a controlled and sterile working environment by directing filtered air in a unidirectional, parallel flow across the workspace. They are commonly used for applications requiring a particle-free environment, such as tissue culture, electronics assembly, and pharmaceutical preparation.

Types of laminar flow cabinets (e.g., vertical, horizontal)

Laminar flow cabinets are available in two main configurations: vertical flow and horizontal flow. Vertical flow cabinets provide downward airflow, suitable for applications involving sterile handling of materials. Horizontal flow cabinets provide a laminar flow of air across the workspace, ideal for protecting samples and materials from contamination.

Applications and benefits of laminar flow cabinets

Laminar flow cabinets are used in various industries, including healthcare, research, and electronics, where maintaining a sterile and particle-free environment is crucial. They offer benefits such as reducing contamination risks, protecting sensitive materials, and providing a clean workspace for delicate procedures.

How laminar flow cabinets provide clean air and particle-free environments

Laminar flow cabinets use high-efficiency particulate air (HEPA) filters to remove airborne particles, ensuring a sterile and clean working area. The filtered air flows smoothly across the workspace, minimizing the risk of contamination.

Important considerations for using laminar flow cabinets

To ensure the optimal performance of laminar flow cabinets, factors such as filter integrity, airflow velocity, and proper handling of materials must be considered. Regular maintenance, filter replacement, and adherence to cleanroom protocols are essential for maintaining the integrity of the particle-free environment.

Comparing Ventilated Devices

By comparing fume hoods, biosafety cabinets, and laminar flow cabinets, their distinct features, such as the level of containment, airflow direction, and intended applications, can be understood. This comparison helps determine which device is most suitable for specific laboratory tasks.

When selecting a ventilated device, factors such as the nature of the materials being handled, the level of protection required, the type of contaminants, and the specific laboratory protocols should be considered. Each device has its strengths and limitations that must align with the intended applications.

While each device serves a specific purpose, there can be instances where their applications overlap. Understanding the limitations and potential areas of overlap is crucial for making informed decisions and ensuring the effectiveness of ventilation systems in the laboratory.

Safety and Regulatory Compliance

Laboratories must adhere to safety guidelines and regulations to protect personnel and ensure compliance with industry standards. Adhering to these guidelines mitigates the risks associated with hazardous substances and ensures the safe operation of ventilated devices.

Proper training, risk assessment, and awareness of potential hazards are essential for laboratory personnel working with ventilated devices. Understanding the safe handling of hazardous materials, proper use of personal protective equipment, and emergency response protocols are vital for maintaining a safe working environment.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA), the Centers for Disease Control and Prevention (CDC), and the National Sanitation Foundation (NSF) provide guidelines and standards for ventilation and laboratory safety. Compliance with these regulations ensures the implementation of best practices and the highest level of safety in laboratory settings.

Emerging Trends and Technologies

Innovations in ventilated devices for improved efficiency and safety

Advancements in ventilation technology have led to innovations such as energy-efficient systems, improved airflow control, and enhanced user interfaces. These innovations aim to improve the efficiency and safety of ventilated devices, providing researchers with better tools for their work.

Integration of smart technologies and remote monitoring capabilities

The integration of smart technologies in ventilated devices allows for remote monitoring, data collection, and control. These advancements enhance the ease of use, enable real-time feedback, and contribute to better overall safety and performance.

Sustainable design and energy-efficient features in ventilated devices

With a growing emphasis on sustainability, ventilated devices now incorporate energy-efficient features and environmentally friendly materials. This promotes responsible energy consumption and reduces the environmental impact of laboratory operations.

Conclusion

Selecting the appropriate ventilated device is crucial for ensuring the safety of laboratory personnel and maintaining the integrity of experiments and samples. Understanding the specific requirements of each task and considering factors such as containment, airflow, and application is essential for making informed decisions.

Proper ventilation plays a pivotal role in creating a safe and healthy working environment in laboratories. By implementing the right ventilated devices, following safety guidelines, and adhering to regulatory standards, laboratories can promote the well-being of personnel and foster the success of scientific research.

Comments are closed.