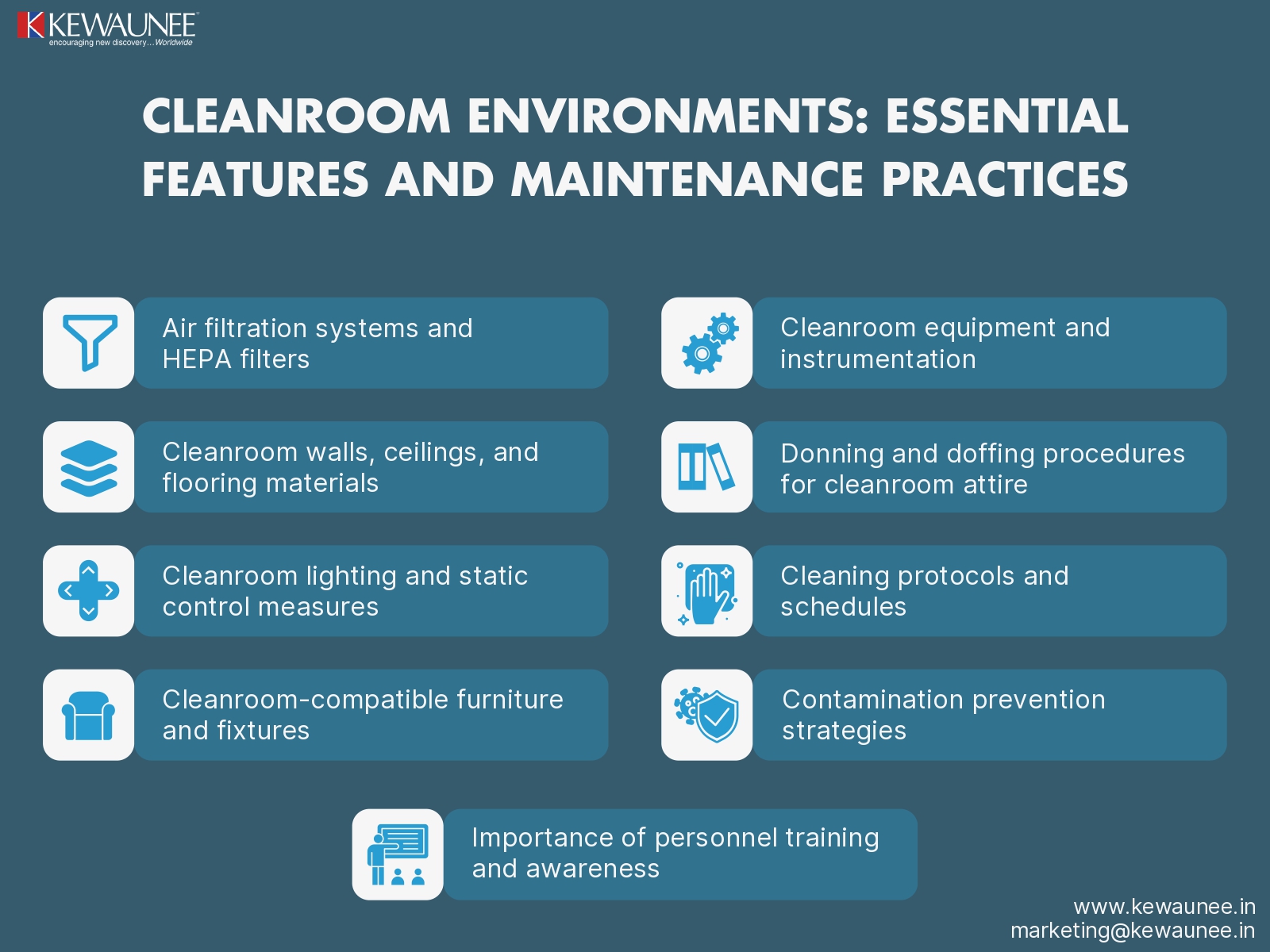

Cleanroom Environments: Essential Features and Maintenance Practices

Cleanroom environments are crucial in various industries where contamination control is paramount to ensure product quality, research integrity, and safety. In this comprehensive guide, we will delve into the world of cleanroom design, exploring the importance of cleanroom environments, the key considerations for designing them, and the essential features and maintenance practices necessary to uphold their integrity.

I. Introduction

Cleanrooms play a vital role in industries such as pharmaceuticals, biotechnology, electronics, and healthcare, where even the tiniest particle or microorganism can compromise the quality of products or research outcomes.

Cleanrooms are classified based on ISO standards that define airborne particle concentration limits, ensuring adherence to specific cleanliness levels and regulatory requirements.

In this guide, we will explore the key aspects of designing and maintaining cleanroom environments, including essential features, design considerations, and maintenance practices that are crucial for achieving and sustaining clean and sterile conditions.

II. Understanding Cleanroom Environments

A. Definition and purpose of cleanrooms

Cleanrooms are controlled environments where the concentration of airborne particles, microorganisms, and other contaminants is minimized to protect sensitive processes, products, or research.

B. Cleanroom classifications and ISO standards

Cleanrooms are classified based on ISO standards, which specify the maximum allowable particle concentration. These classifications help define the cleanliness level required for different applications.

C. Key considerations for cleanroom design

Designing a cleanroom involves careful consideration of factors such as airflow patterns, filtration systems, temperature and humidity control, as well as the specific needs and requirements of the industry or application.

III. Designing Cleanroom Facilities

A. Cleanroom layout and space planning

Efficient cleanroom layouts optimize workflow, minimize contamination risks, and segregate different cleanroom zones based on cleanliness requirements.

B. HVAC systems for cleanroom environments

Heating, ventilation, and air conditioning (HVAC) systems in cleanrooms are designed to maintain precise control over temperature, humidity, airflow direction, and filtration to ensure the desired cleanliness level.

IV. Essential Features of Cleanrooms

A. Air filtration systems and HEPA filters

Air filtration systems, including High-Efficiency Particulate Air (HEPA) filters, remove airborne particles, dust, and microorganisms, ensuring a clean and sterile environment.

B. Cleanroom walls, ceilings, and flooring materials

Cleanroom surfaces must be smooth, non-porous, and easy to clean to prevent particle shedding and facilitate effective decontamination.

C. Cleanroom lighting and static control measures

Cleanroom lighting should meet specific requirements, providing adequate illumination without generating excessive heat or introducing particles. Static control measures minimize electrostatic discharge risks.

V. Cleanroom Furniture and Equipment

A. Choosing cleanroom-compatible furniture and fixtures

Cleanroom furniture and fixtures must be made of non-shedding, easy-to-clean materials to minimize particle generation and contamination risks.

B. Cleanroom equipment and instrumentation

Selecting equipment and instruments suitable for cleanroom use is essential to prevent contamination and maintain the desired cleanliness level. Proper handling, cleaning, and maintenance are critical.

VI. Cleanroom Garments and Personal Protective Equipment (PPE)

A. Cleanroom garment requirements and classifications

Cleanroom garments, such as coveralls, hoods, gloves, and shoe covers, protect both personnel and products from contamination. They are designed to minimize particle shedding.

B. Donning and doffing procedures for cleanroom attire

Strict procedures for donning and doffing cleanroom attire are necessary to prevent contamination during gowning and degowning processes.

C. Importance of proper PPE usage and maintenance

Adhering to proper PPE usage guidelines and following appropriate maintenance procedures ensure that personnel minimize contamination risks and maintain the integrity of the cleanroom environment.

VII. Cleanroom Cleaning and Maintenance

A. Cleaning protocols and schedules

Implementing regular cleaning schedules, using suitable cleaning agents and techniques, and paying attention to cleanliness during maintenance activities are crucial for preserving cleanroom conditions.

B. Regular monitoring and testing of cleanroom conditions

Periodic monitoring of particle count, air quality, temperature, and humidity levels ensures that cleanroom conditions remain within the desired parameters. This allows for timely intervention and maintenance.

VIII. Cleanroom Contamination Control

A. Contamination prevention strategies

Strict protocols for personnel entry and exit, controlled material handling, and rigorous cleaning and disinfection procedures minimize the risk of contamination in cleanroom environments.

B. Handling hazardous materials and waste disposal in cleanrooms

Proper storage, handling, and disposal of hazardous materials and waste are essential to prevent contamination and maintain a safe working environment.

IX. Training and Education for Cleanroom Personnel

A. Cleanroom protocols and standard operating procedures (SOPs)

Thorough training on cleanroom protocols and SOPs is crucial for personnel to understand and adhere to proper cleanroom practices.

B. Importance of personnel training and awareness

Continuous training and educational programs ensure that cleanroom personnel stay updated on best practices, industry regulations, and contamination prevention techniques.

C. Ongoing education and skill development programs

Regular education and skill development initiatives contribute to the growth and expertise of cleanroom personnel, fostering a culture of continuous improvement in cleanroom environments.

X. Regulatory Compliance and Documentation

A. Adherence to cleanroom standards and guidelines

Compliance with relevant cleanroom standards, such as ISO 14644, ensures that cleanroom facilities meet the required cleanliness levels and adhere to industry-specific regulations.

B. Audits and inspections for cleanroom facilities

Regular audits and inspections, whether conducted internally or by regulatory bodies, ensure compliance, identify areas for improvement, and verify the effectiveness of cleanroom operations.

XI. Conclusion

Throughout this guide, we covered the importance of cleanroom environments, the key considerations for designing them, and the essential features and maintenance practices required to create and sustain clean and contamination-free environments.

Implementing essential features and adhering to proper maintenance practices are critical for achieving optimal cleanliness levels, meeting industry standards, and ensuring the safety and integrity of products, research, or processes conducted within cleanroom environments.

By following the guidelines and best practices outlined in this guide, organizations can create and maintain cleanroom environments that safeguard against contamination, adhere to industry regulations, and uphold the highest standards of quality and safety.

Comments are closed.