From Reactive to Predictive: The New Era of Preventive Fume Hood Maintenance

The majority of laboratory mishaps start not with a spectacular breakdown but rather with a hush. A barely noticeable alteration in airflow, an uncommon noise, or a hood that seems slightly heavier than normal are all among the silent clues that usually go unnoticed until the problem escalates. For many years, laboratories have been functioning in a mode where they responded to situations, that is, problems were solved only after the quality of work had deteriorated or safety had been threatened. However, that way of thinking is being transformed now.

Modern laboratories are shifting toward preventive and predictive maintenance strategies that identify risks before they turn into disruptions. At the center of this transition is the Fume Hood, no longer viewed as a static installation, but as a living system that demands continuous attention and intelligence.

Why Reactive Maintenance Is No Longer Enough

Reactive maintenance depends on the manifestation of a problem. A part gets broken, the airflow experiencing a drop, or a safety inspection raises a concern. Even though this method might appear to be financially wise in the short run, it involves risks that are not so apparent.

Whenever the apparatus is not functioning as it should, research is put on hold and new plans have to be made. Furthermore, the cost of emergency maintenance is usually higher than that of a regular service. Extremely important, if a problem is not detected early enough it may escalate to the point where users are at risk before the issue is even acknowledged.

In laboratories that conduct research where the stakes are very high, the strategy of waiting for a failure has been ruled out. Prevention has been redefined as a necessity rather than an option.

Understanding the Real Role of Containment Systems

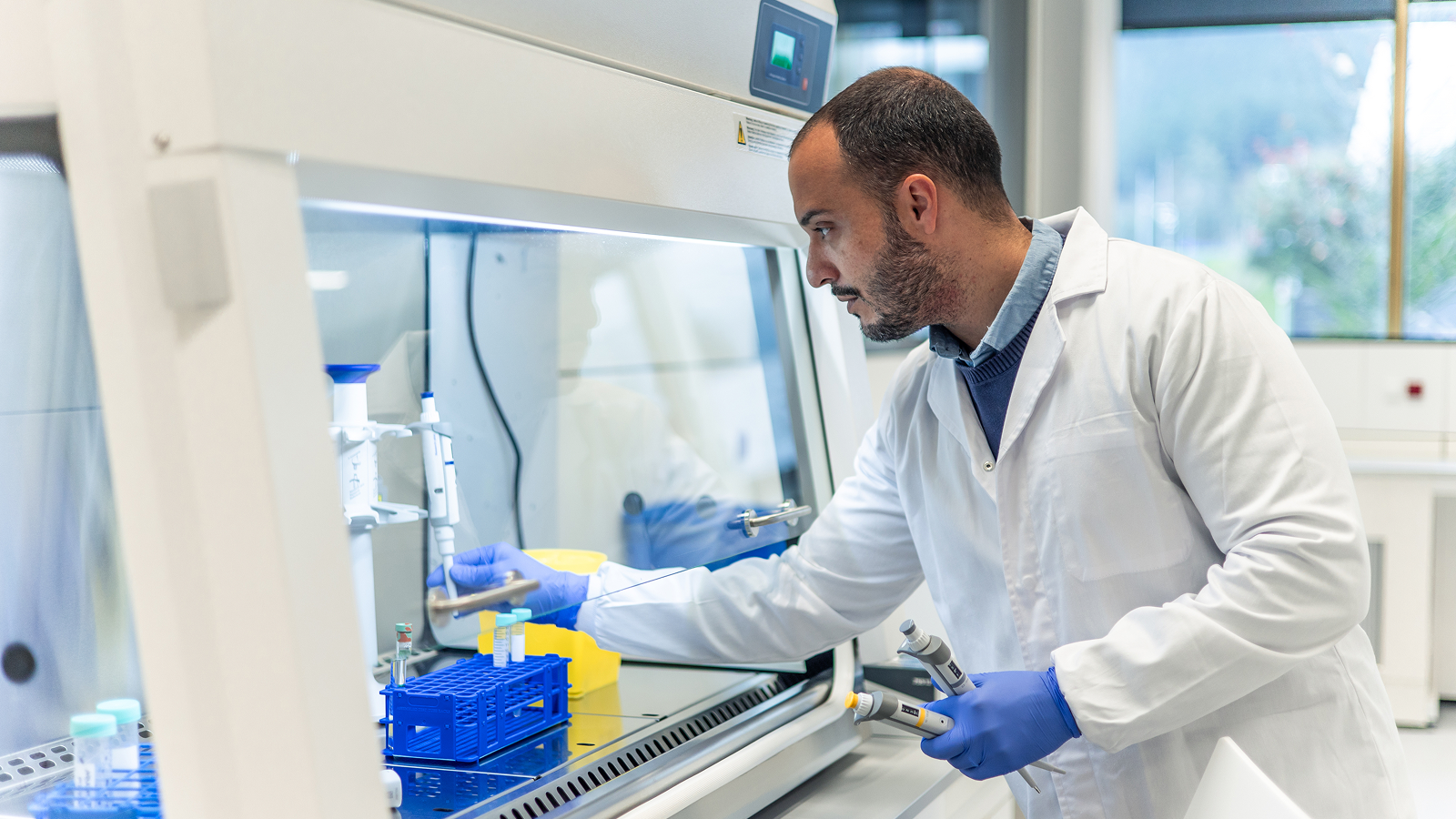

Laboratory containment systems work silently in the background, protecting users from hazardous fumes, vapors, and aerosols. Whether installed as a benchtop system or a walk-in configuration, a fume cabinet plays a continuous role in maintaining safe working conditions.

Over time, however, even well-designed systems experience wear. Mechanical components drift out of calibration. Filters and liners degrade. Usage patterns change, placing unexpected demands on airflow performance. Without structured monitoring and maintenance, these changes go unnoticed.

Preventive maintenance begins with acknowledging that containment performance is dynamic, not fixed.

The Shift Toward Preventive Thinking

Preventive maintenance focuses on routine inspections, scheduled servicing, and performance verification. Instead of reacting to breakdowns, laboratories adopt structured checklists and service intervals designed to preserve optimal operation.

This approach delivers clear advantages:

- Consistent containment performance

- Reduced emergency repair costs

- Improved compliance with safety standards

- Longer equipment lifespan

A well-maintained Fume Hood supports daily research without drawing attention to itself, which is exactly how safety systems should function.

Predictive Maintenance: The Next Step Forward

While preventive maintenance relies on schedules, predictive maintenance relies on insight. By monitoring performance indicators over time, laboratories can anticipate issues before they occur.

Modern containment systems increasingly support:

- Airflow monitoring and alarms

- Usage trend analysis

- Sash position tracking

- Maintenance alerts based on actual wear

This data-driven approach allows maintenance teams to intervene precisely when needed, rather than too early or too late. Predictive strategies reduce waste, minimize disruption, and increase confidence in safety performance.

What Preventive Maintenance Really Protects

It is easy to think of maintenance as protecting equipment. In reality, it protects people, research integrity, and organisational reputation.

A poorly maintained fume cabinet can compromise containment without obvious warning signs. Vapors may escape at the edges of the sash. Turbulence can increase exposure risk. Over time, even minor performance losses can create unsafe conditions.

Preventive maintenance safeguards:

- Research personnel

- Experimental accuracy

- Regulatory compliance

- Facility uptime

In regulated environments, documented maintenance also plays a critical role during audits and inspections.

Designing for Maintainability

Effective maintenance begins at the design stage. Systems engineered for easy access, durable materials, and clear service points reduce long-term effort and cost. Thoughtful design allows inspections and servicing to occur without disrupting laboratory operations.

Features that support maintainability include:

- Robust frame construction to minimize realignment needs

- Smooth, cleanable interior surfaces

- Accessible airflow components

- Durable sash mechanisms

A Fume Hood designed with maintenance in mind performs more consistently across its entire lifecycle.

Partnering With Experience

Preventive and predictive methods are not only dependent on instruments. They also need specialists. The knowledge of how systems change their course throughout time, different applications, and environments is crucial in formulating maintenance programs that work effectively.

Kewaunee gradually incorporates many years of laboratory engineering experience in its every containment solution. The mixture of product design, performance testing, and service knowledge enables Kewaunee to make laboratories transition without any doubts from reactive solutions to proactive safety management.

Such a partnership approach ensures that laboratories get support during the installation phase and also through years of operation.

Building a Culture of Prevention

Technology in itself will not provide the preventive maintenance of the future. It needs a healthy organizational culture around it. The labs that win in predictive strategies have users that inform even the tiniest change, teams that are trained to detect the early warning signs, and maintenance that is considered a daily operation rather than a disturbance.

When scientists are aware that reporting a problem is a step towards the prevention of downtime, all will gain. Safety is no longer just one item on the checklist but a shared responsibility.

The Long-Term Payoff

The benefits of preventive and predictive maintenance compound over time. Systems last longer. Budgets become more predictable. Safety incidents decline. Research productivity improves.

Most importantly, laboratories gain peace of mind. Knowing that containment systems are monitored, maintained, and supported allows researchers to focus fully on discovery.

A modern fume cabinet is not just an installation. It is an ongoing commitment to safety, reliability, and excellence.

Conclusion

The future of laboratory safety lies in anticipation, not reaction. Preventive and predictive maintenance strategies transform containment systems from passive equipment into actively managed assets. By moving beyond emergency repairs and embracing performance insight, laboratories protect people, preserve research integrity, and ensure long-term operational confidence. The evolution of the Fume Hood reflects this shift clearly, marking a new era where safety is continuously reinforced rather than periodically restored.

Are you ready to move from reactive maintenance to a preventive, future-ready approach? Connect with us today.

Comments are closed.