HVAC For Laboratories Key Design Parameters

HVAC (heating, ventilation, and the air conditioning system) helps in keeping up acceptable indoor air quality (IAQ) through satisfactory ventilation with filtration and thermal comfort. Exhaust air is defined as air eliminated from a space and released to outside the building through mechanical (such as motor-driven fans or blowers) and normal ventilation frameworks (such as through doors or windows).

WHY DESIGNING LABORATORY VENTILATION & EXHAUST IS NECESSARY?

The risk of exposure of hazardous chemicals in labs ranges from negligible to severe. For this reason, there must be an adequate level of protection that is provided through different ventilation systems, exhaust systems, or exposure control devices, such as fume hoods.

Therefore, the key purposes of designing lab exhaust & ventilation are:

- Removal of odors and contaminants.

- Higher air flows to assist cooling.

- Prevent overexposure to hazardous chemicals.

- Satisfy humidity and temperature requirements.

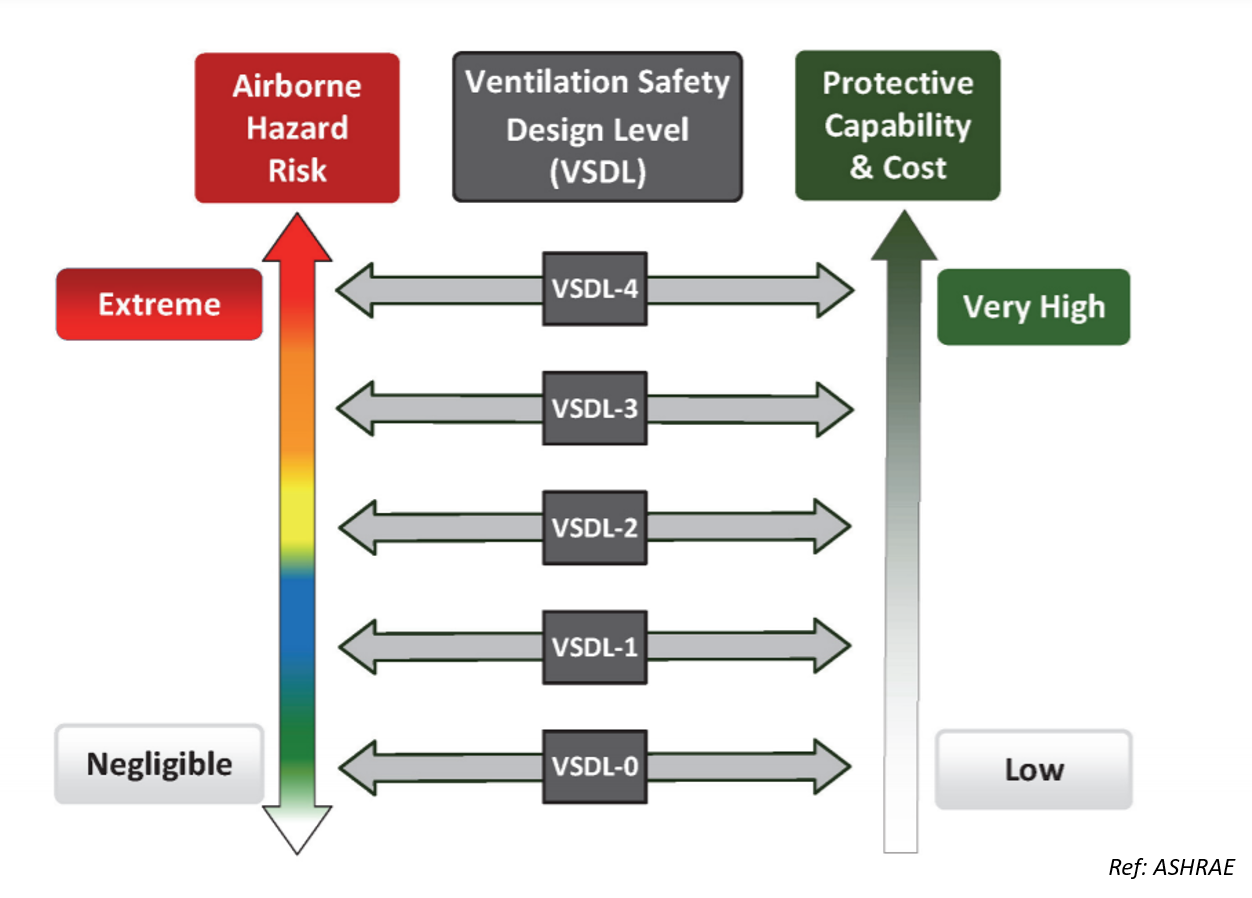

LEVELS OF VENTILATION DESIGNS FOR LABORATORY

The essential elements of the different levels of lab ventilation designs are to give protected and breathable conditions for all lab personnel, and to limit openings to dangerous air impurities. Careful designing, planning, and keeping up air supply/ exhaust ventilation designs can achieve these objectives.

KEY DESIGN CONSIDERATIONS FOR LABORATORY VENTILATION & EXHAUST SYSTEM

- All labs will be isolated from outside regions i.e., there will be no return of lab exhaust or fume hood back into the center.

- Labs exhaust frameworks ought to be planned with an abundance limit (say 25%) for spikes and future extension.

- Electrical appliances, such as freezers, hatchery, autoclave, regularly exhaust heat into a room. Contemplate the impact of a warm place during the lab planning phase.

- The air balance of the room shall be maintained by closing the windows. Hence climate control should be provided.

- Local exhaust ventilation other than fume hoods such as snorkels shall be provided in labs to maximize control effectiveness or exposure to hazardous chemicals.

- In design exhaust system of labs, airflow can be measured by anemometer – a device that measure the air speed. As measuring air speed is important, to predict the weather change.

- Laboratory exhaust fans will be spark proof and must be on the highest-level roof of the building as it will minimize the risk of interaction between the personnel and exhaust air. And hoods will be labelled to show the fan or ventilation system to which they are associated.

- Air exhausted from laboratory will not go un-ducted through different regions.

- Ventilation supply or exhaust conversion can make the entryways hard to open. Consider programming in a brief pause into the alarm framework.

Designing your laboratory airflow right will lower energy consumption and improve the air quality and safety of your lab. Finally, whether you are constructing a new plan or renovating an existing one, talk to one of our experts to plan the lab ventilation. We use our decades of expertise & advanced technologies, such as Computational fluid dynamics (CFD), to help get your lab design right.

Comments are closed.