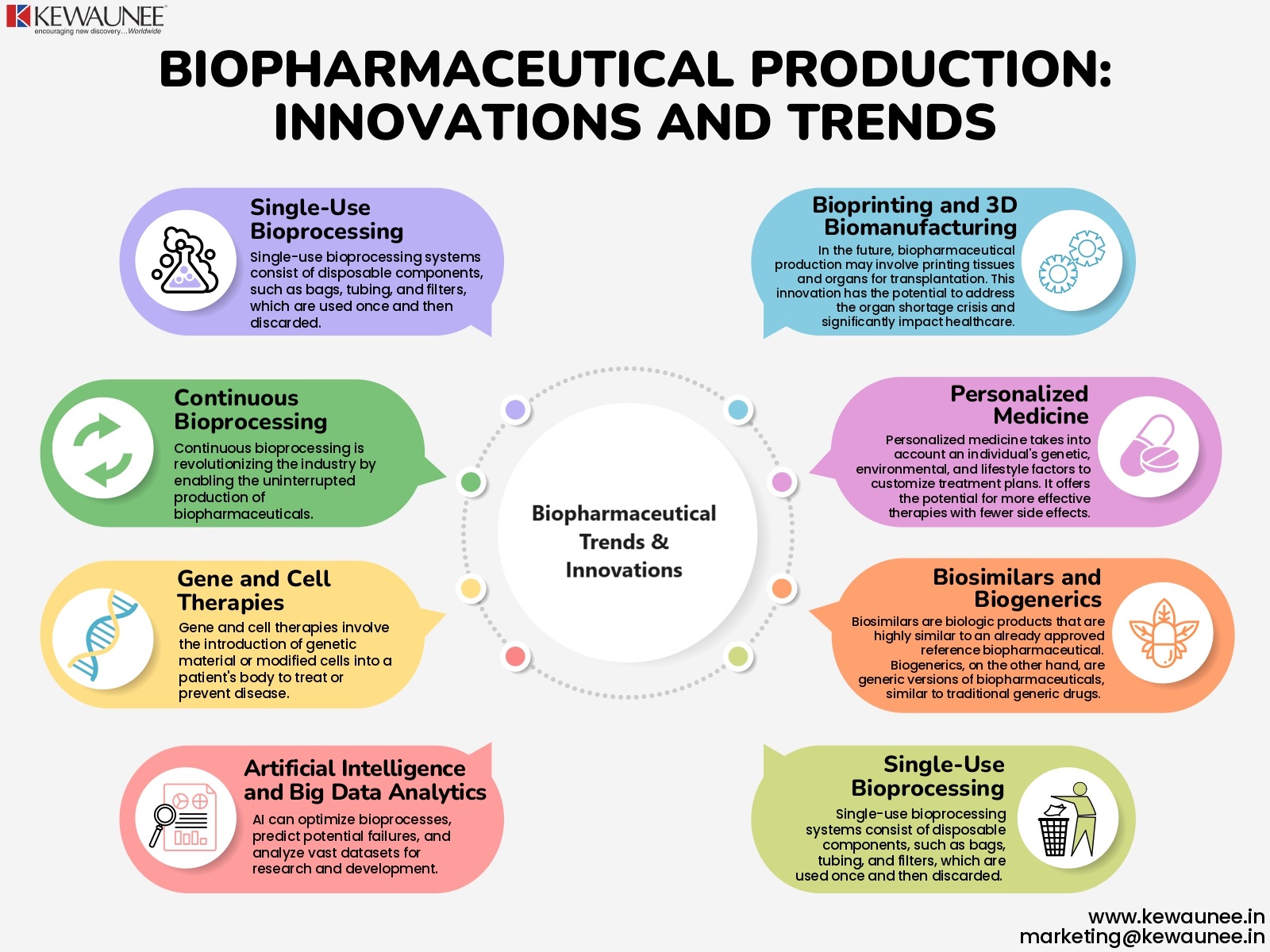

Biopharmaceutical Production: Innovations and Trends

Biopharmaceutical production is on the cusp of a transformative era. As science, technology, and manufacturing practices continue to evolve, the biopharmaceutical industry is poised for significant advancements.

This blog explores the exciting innovations and trends that will shape the future of biopharmaceutical production.

1. Introduction

The production of biopharmaceuticals, including vaccines, monoclonal antibodies, and other therapeutic proteins, plays a pivotal role in healthcare. Biopharmaceuticals offer targeted and often curative treatments for various diseases.

To meet the growing demand for these life-saving therapies, the biopharmaceutical industry is embracing cutting-edge innovations and adopting new trends.

2. Single-Use Bioprocessing

Traditional stainless-steel bioreactors are giving way to single-use bioprocessing technologies. Single-use systems offer several advantages, including reduced risk of cross-contamination, flexibility in scaling production, and faster setup. This trend is expected to continue growing as it enhances the efficiency and cost-effectiveness of biopharmaceutical manufacturing.

Single-use bioprocessing systems consist of disposable components, such as bags, tubing, and filters, which are used once and then discarded. This approach eliminates the need for extensive cleaning and sterilization, significantly reducing the risk of cross-contamination between batches.

It also allows for rapid changeovers, making it easier to switch between different products or production scales. Single-use systems are particularly beneficial for small-batch or clinical-scale production, where flexibility and speed are crucial.

3. Continuous Bioprocessing

Continuous bioprocessing is revolutionizing the industry by enabling the uninterrupted production of biopharmaceuticals. This approach reduces batch-to-batch variability, improves product consistency, and lowers production costs. The adoption of continuous bioprocessing represents a significant shift from the conventional batch processing, promising increased efficiency and quality.

In traditional batch processes, production occurs in discrete steps, with each step followed by cleaning, sterilization, and the transfer of materials. Continuous bioprocessing, on the other hand, involves the continuous flow of materials through interconnected unit operations.

This approach eliminates the need for lengthy cleaning and setup procedures between batches, reducing the risk of errors and contamination. Continuous bioprocessing is well-suited for high-volume production and offers advantages such as better control of critical process parameters, reduced labor requirements, and shorter production times.

4. Gene and Cell Therapies

Gene and cell therapies have gained immense attention in recent years for their potential to treat previously incurable diseases. This trend is set to continue as research in gene and cell therapy advances, creating new opportunities for biopharmaceutical production. The industry will need to adapt to the unique challenges of producing personalized, patient-specific treatments.

Gene and cell therapies involve the introduction of genetic material or modified cells into a patient’s body to treat or prevent disease. These therapies have shown remarkable success in treating conditions such as certain types of cancer, genetic disorders, and autoimmune diseases. The production of gene and cell therapies requires specialized processes to ensure the safety and efficacy of the final product.

Biopharmaceutical manufacturers are developing innovative production methods to meet the demands of gene and cell therapies. These therapies often involve small batch sizes, strict quality control, and specialized manufacturing techniques. The industry is investing in facilities equipped with cutting-edge technology to support the production of these revolutionary treatments.

5. Bioprinting and 3D Biomanufacturing

The integration of bioprinting and 3D biomanufacturing techniques is set to revolutionize tissue engineering and regenerative medicine. In the future, biopharmaceutical production may involve printing tissues and organs for transplantation. This innovation has the potential to address the organ shortage crisis and significantly impact healthcare.

Bioprinting is a technique that uses 3D printers to create biological structures by depositing layers of living cells, biomaterials, and growth factors. This technology holds immense promise for creating replacement tissues and organs, offering hope to patients on transplant waiting lists. The ability to print custom-designed organs can potentially eliminate the need for donors and reduce the risk of rejection.

3D biomanufacturing extends beyond organ printing to the creation of tissue models for drug testing and disease research. These models can be used to study diseases, develop and test new drugs, and better understand complex biological processes. The integration of bioprinting and 3D biomanufacturing is a game-changer for biopharmaceutical production and regenerative medicine.

6. Artificial Intelligence and Big Data Analytics

Artificial intelligence (AI) and big data analytics are poised to transform biopharmaceutical production. AI can optimize bioprocesses, predict potential failures, and analyze vast datasets for research and development. The industry will increasingly rely on AI-driven decision-making and predictive analytics to enhance efficiency.

AI and big data analytics have the potential to revolutionize various aspects of biopharmaceutical production. AI algorithms can analyze vast datasets to identify patterns, optimize process parameters, and predict potential issues, leading to more efficient and consistent production. Machine learning models can assist in drug discovery, protein engineering, and predictive maintenance of manufacturing equipment.

Big data analytics also play a crucial role in drug development. By analyzing large sets of data, such as genomics, proteomics, and clinical trial results, researchers can identify novel drug targets, optimize therapeutic proteins, and streamline clinical trial design. These data-driven approaches save time and resources in the development of biopharmaceuticals.

7. Personalized Medicine

The era of personalized medicine is dawning. Biopharmaceutical production is shifting towards tailoring treatments to individual patients based on their genetic makeup and specific needs. This trend is driven by advancements in genomics and the development of therapies designed for specific patient populations.

Personalized medicine takes into account an individual’s genetic, environmental, and lifestyle factors to customize treatment plans. It offers the potential for more effective therapies with fewer side effects. Biopharmaceutical production is adapting to produce therapies that target specific genetic markers or mutations, making treatments more precise and patient-centered.

This trend is especially significant in oncology, where targeted therapies are designed to attack cancer cells while sparing healthy tissue. As genomics and diagnostic tools continue to advance, personalized medicine will become more accessible and commonplace in healthcare.

8. Biosimilars and Biogenerics

The production of biosimilars and biogenerics is gaining momentum. These products offer cost-effective alternatives to expensive biopharmaceuticals, increasing accessibility to critical treatments. The market for biosimilars is expected to expand significantly in the coming years.

Biosimilars are biologic products that are highly similar to an already approved reference biopharmaceutical. They offer a cost-effective alternative to the original product while maintaining comparable safety and efficacy. The development and production of biosimilars require rigorous testing and regulatory approval to ensure their similarity to the reference product.

Biogenerics, on the other hand, are generic versions of biopharmaceuticals, similar to traditional generic drugs. They are typically less expensive than the original biopharmaceutical, making essential treatments more accessible to a broader patient population. The production of biosimilars and biogenerics is contributing to healthcare cost reduction and improved patient access to critical therapies.

9. Regulatory Advancements

Regulatory agencies are adapting to the evolving landscape of biopharmaceutical production. They are developing guidelines and frameworks to support innovations while ensuring safety and quality. This regulatory flexibility is essential for the industry to embrace new technologies and processes.

Regulatory agencies play a crucial role in ensuring the safety and efficacy of biopharmaceutical products. As the industry undergoes significant transformations, regulatory bodies are working to provide clear guidance on new technologies and production methods. They are adopting risk-based approaches to regulatory oversight and streamlining approval processes.

The regulatory landscape is evolving to support the development and production of innovative biopharmaceuticals. Regulatory advancements are essential for maintaining high standards of safety and quality while allowing the industry to explore new frontiers in biopharmaceutical production.

Conclusion

The future of biopharmaceutical production is filled with promise and innovation. From single-use bioprocessing to personalized medicine and the integration of AI, the industry is on the brink of transformative change. These advancements will not only improve the efficiency of biopharmaceutical manufacturing but also enhance the quality of treatments and expand access to life-saving therapies. As science and technology continue to advance, the future of biopharmaceutical production is bright, offering hope to patients around the world.

Comments are closed.