What Is ASHRAE Testing And Why It Matters?

Laboratories deal with harmful chemicals, hazardous materials, and poisonous gases. In the interest of lab users’ safety, harmful gases and fumes are drawn out of user zone and exhausted out of the labs.

Laboratory fume hood is a safety enclosure found mostly in all chemical laboratories. Fume hoods draws the air through the face of the fume hood and away from the users and labs. Through ventilation, fume hoods minimize the risk of contamination.

But, how to know if the fume hood is doing its job properly?

FUME HOOD TESTING & DIAGNOSTIC

Testing and certifying the fume hoods before handing over the project to customers is essential to ensure the hood users and lab personnel are safe. Testing and diagnostic tools help validate the fume hood performance.

Furthermore, fume hood testing & certification also helps identify problems & potential risks involved with HVAC, pressurization, and equipment location related issues. Even a brand-new fume hood will have to be tested before lab activities commence.

That’s where ASHRAE comes into the picture. ASHRAE, a widely accepted standard across the globe, has set testing guidelines prescribing the methods & procedures to rate the fume hood performance.

ABOUT ASHRAE SOCIETY

American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) is a global society focusing on building systems, energy efficiency, indoor air quality, thermal comfort, commissioning, refrigeration, and sustainability. ASHRAE society and its members help define standards and guidelines for the industry at large.

ASHRAE was formed in 1959 by the merger of the American Society of Heating and Air-Conditioning Engineers (ASHAE), founded in 1894, and the American Society of Refrigerating Engineers (ASRE), founded in 1904. ASHRAE’s goal is to serve as a source of technical standards and guidelines in the file of HVAC & related industry.

ASHRAE STANDARD 110-2016 TESTING

Turning our focus back to fume hoods, ASHRAE standard 110-2016 (commonly referred to as ASHRAE 110) provides “Methods of Testing Performance Laboratory Fume Hoods” to provide a quantitative and qualitative test method to gauge a laboratory fume hood’s level of containment. The latest ASHRAE guidelines released in 2016, is an upgrade over the previous version released in 1995.

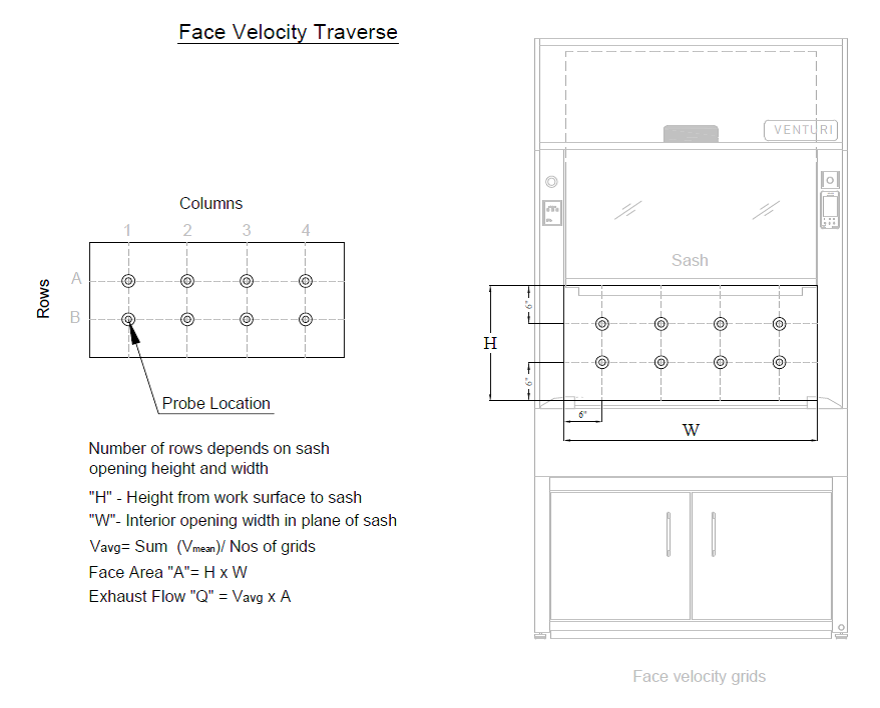

Face velocity measurements: This test provides a qualitative evaluation of air capture at the face of the fume hood by proving effectiveness and ensuring operator safety. Sash openings for the fume hood being tested are set to operating height as defined by the end user. We measure face velocity in a grid pattern to determine an average face velocity and observe the uniform air flow through the plane of the sash.

Flow visualization testing: The smoke challenge is executed in two ways; local challenge and large volume challenge. The local challenge shows the flow around the opening of and just inside the hood. The large volume challenge demonstrates the air patterns inside the hood. Observations from the demonstrations are used to test the performance of the fume hood.

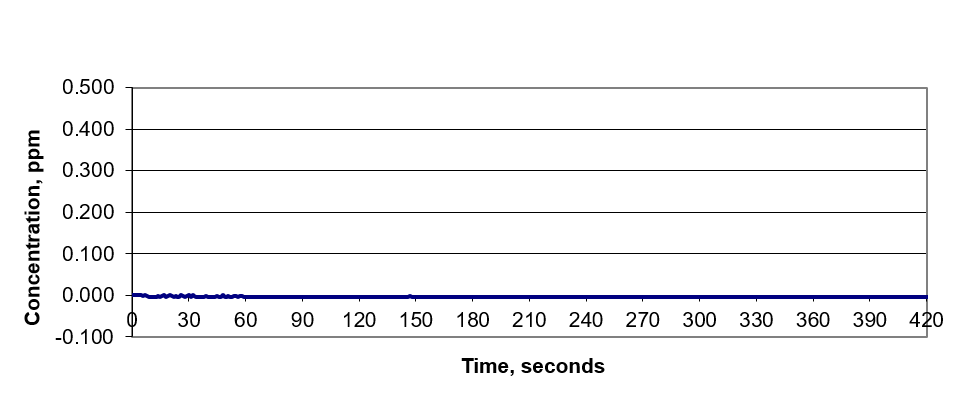

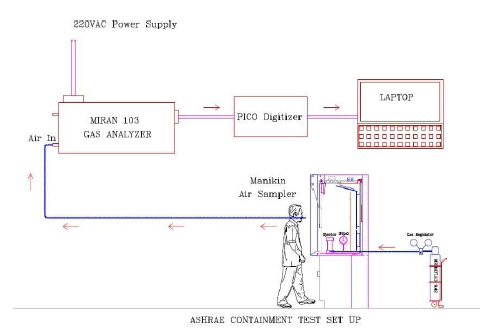

Tracer Gas test: Face velocity had been used historically as the primary indicator of fume hood performance, however tracer gas containment test reveal that face velocity test alone is an inadequate indicator of fume hood performance. Tracer gas tests provide quantitative data evaluating the containment performance of fume hoods. Therefore, the tracer gas test is the ultimate test for the containment of a fume hood.

The test simulates a lab technician using a fume hood. Tracer gas test uses a mannequin to represent the lab technician, and a probe is placed in what would be the technicians breathing zone. The probe runs to an analyzer that logs the tracer gas concentration while testing. The tracer gas flows through an ejector at a set rate. We report the performance of the hood based on the results of the test.

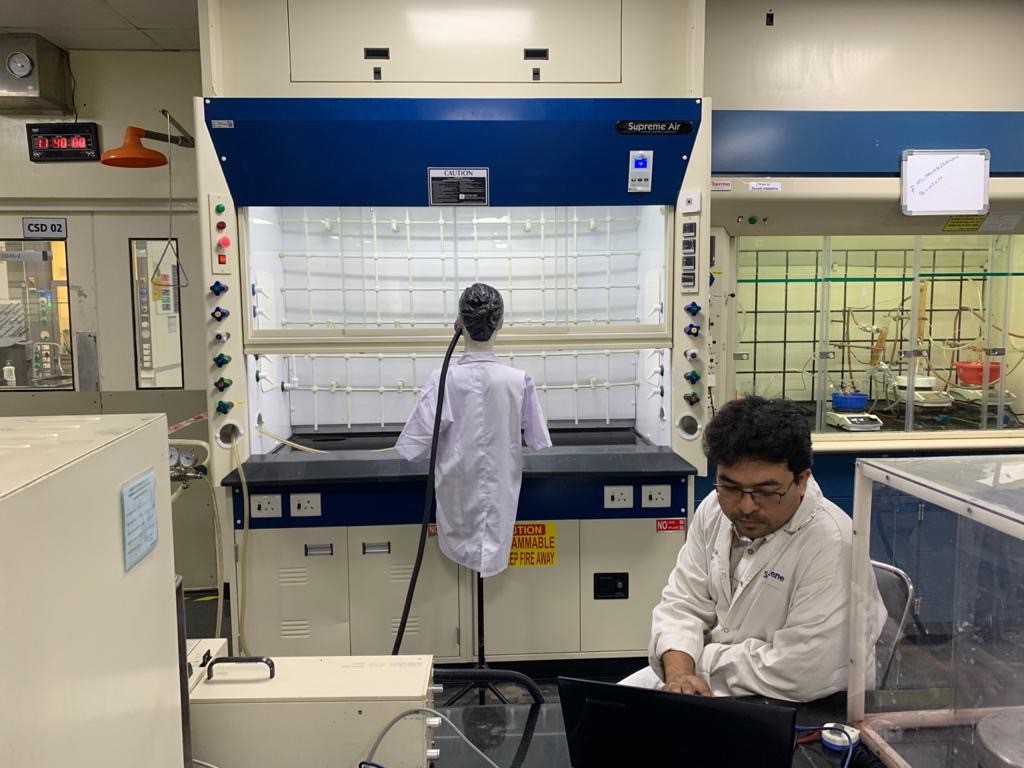

CONDUCTING ASHRAE TESTS

A hot-wire anemometer is used for fume hood face velocity test using. Ensure that the supply air system is switched on and maintains slightly negative pressure w.r.t the adjacent area. See that no cross drafts in front of the hood which hamper fume hood performance.

The procedure is:

- An imaginary grid shall be formed with spaces less than 1 ft2 with the larger side no greater than 13 in

- The measuring probe shall be mounted on an adjustable stand and not handheld. It is important to stand out of the way when measuring airflow

- The readings shall be taken from the center of each grid rectangle at a rate of one per second for 20 seconds and averaged by the reading device.

The recorded average for each grid shall be averaged to give the total average face velocity for the fume hood.

For smoke visualization testing, a source of visible smoke shall be present to generate small controlled volumes inside the fume hood. Drager airflow tester, MSA, wizard stick are some of the smoke tubes available in the market. We should keep the composition of some smoke generated in mind as they might be corrosive or hazardous, such as titanium tetrachloride. One should always be careful about the hazards these devices may cause.

The local visualization challenge testing procedure is:

- Smoke shall be released under the airfoil

- Smoke shall be released along the sidewalls

- Smoke shall be released along the work surface

- Smoke shall be released around any equipment that may be in the way

- Smoke shall be released inside the hood above the bottom of the sash

- Smoke shall be released behind the sash for horizontal sash or combination sash hoods

- Smoke shall be released in the cavity above the hood opening

- Smoke shall be released outside the hood

For large smoke visualization testing, a source of visible smoke shall be available to generate a large volume of smoke in the fume hood. It is important that the apparatus generating the smoke does not produce an air velocity high enough that it affects the airflow pattern inside the hood. Rosco Fog generator is the one of the commonly used smoke generators. Dry ice can also be used for this purpose. Place a bowl inside the hood worktop containing a piece of dry ice and hot water is poured which releases large amount of smoke to visualize the air movement inside the hoods.

The large volume visualization challenge testing procedure is:

- Smoke shall be released under the airfoil

- Smoke shall be released along the sidewalls

- Smoke shall be released along the work surface

- Smoke shall be released around any equipment that may be in the way

- Smoke shall be released inside the hood above the bottom of the sash

- Smoke shall be released behind the sash for horizontal sash or combination sash hoods

- Smoke shall be released in the cavity above the hood opening

- Smoke shall be released outside the hood

The tracer gas used for testing shall be sulfur hexafluoride, SF6 with 99.9% purity. Sulfur hexafluoride (SF6) is an inorganic, colorless, odorless, non-flammable, non-toxic but extremely potent greenhouse gas. It has a density of 6.12 g/L at sea level conditions, considerably 6 times heavier than the density of air (1.225 g/L), this is one of the main reason why SF6 gas is used.

The cylinder shall be capable of maintaining 30 psi at a release rate of at least 4 Lpm for 30 minutes. Normally 10 kg cylinder would be ideal for shipping to jobsites, as these gas cylinders contain gas under pressure.

However, do note that SF6 is not good for the environment due to its greenhouse effect, so a lot of places are limiting its use. Unfortunately, there is not a great substitute at this point. ASHRAE is studying new gases to determine the best one to use, but it may be years before we have a concrete alternative.

- Ejector System: The ejector for the tracer gas will follow specifications provided in the ASHRAE 110.

- Detection Instruments: The detector instrument shall be a continuous reading instrument set up for the tracer gas. A minimum detection range of 0.01 to 20 ppm is required. The instrument will be accurate to ± 10% of the reading or 0.025, whichever is greater. The instrument will can log data digitally.

- Mannequin: The mannequin shall be a three-dimensional mannequin that accurately portrays human proportions. The mannequin will be clothed in a smock, coveralls, or clothing typical to that worn in a laboratory setting.

- Tracer Gas Test Procedure

The Miran-103 is the commonly used specific gas analyzer. Recently, I found there are few other companies producing similar gas analyzers for containment testing on hood. The stepwise procedure to conduct the containment test using Miran-103 equipment are:

- The Miran-103 shall be given sufficient time to warm up and adjust to the conditions in the room.

- We shall test the functionality of the instrument using the closed-loop method before testing a hood can begin.

- For typical fume hoods with vertical rising sashes the gas ejector shall be tested in 3 unique positions. These positions, unless otherwise specified, are – 12 inches from the left sidewall, equidistant from both sidewalls, and 12 inches from the right sidewall.

- The aluminum barrel of the ejector shall be positioned 6 inches behind the sash with the bonnet extending 1 inch closer to the sash.

- The mannequin shall have a probe attached at the breathing zone. The end of this probe shall be located 6 inches from the plane of the sash, or 3 inches from the plane of the sash, and 22 inches above the plane of the worktop.

- The gas shall be turned on and given 30 seconds before recording data.

Data shall be recorded for 5 minutes with readings being taken at least every second. Using Pico Digitizer, we can monitor and record the data on the laptop/computer for documentation and reports.

After testing at every position, we record the performance rating of the hood as the highest control level recorded for all the positions.

- Sash Movement Containment Test

- The sash movement containment test shall be a 2-minute test that occurs at the end of each 5-minute Tracer Gas Test.

- The sash shall be opened and closed every 30 seconds 3 times.

- The performance rating for the sash movement effect (SME) shall be recorded as the highest control level recorded for all the positions.

PERFORMANCE RATING

Comments are closed.