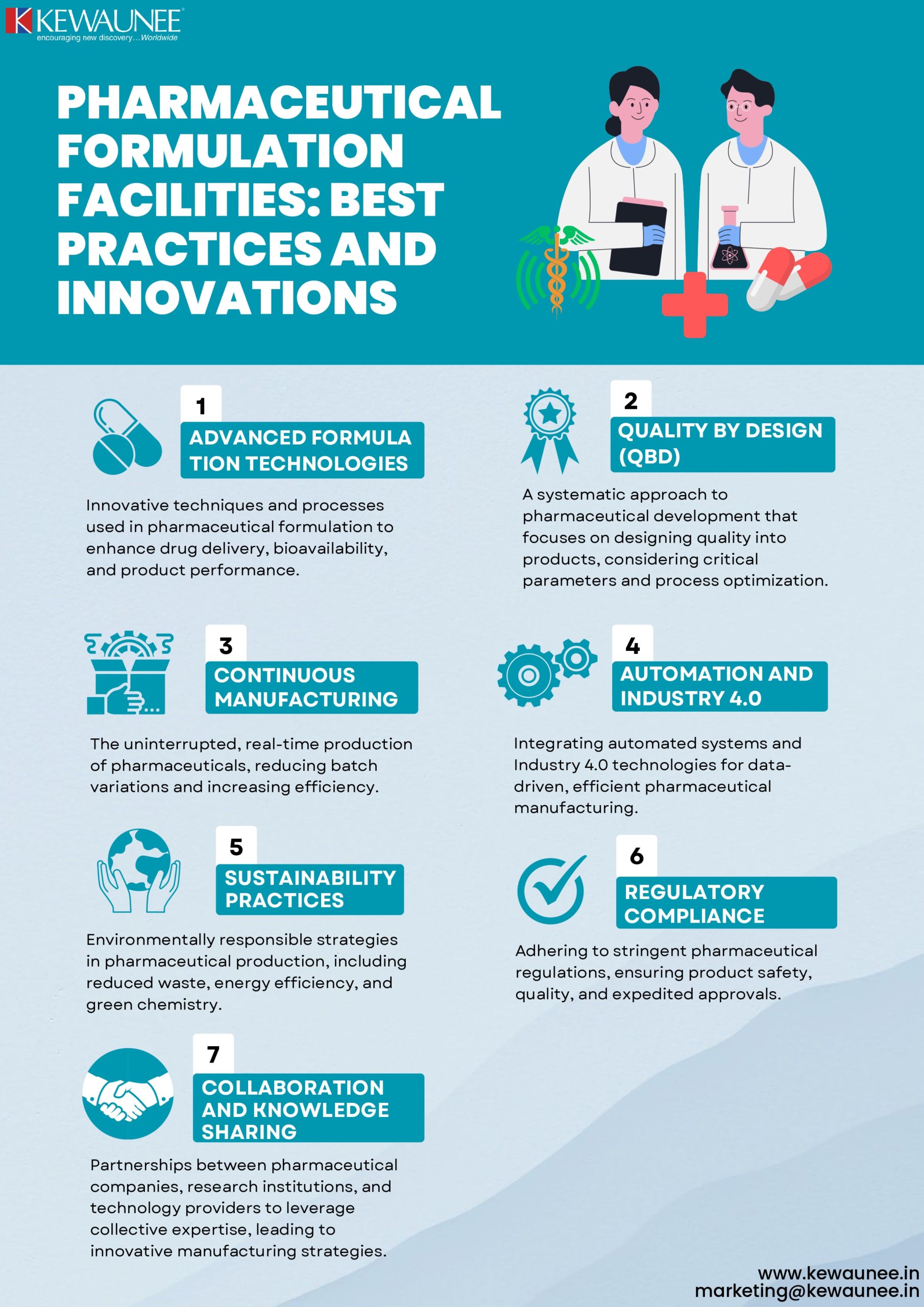

Pharmaceutical Formulation Facilities: Best Practices and Innovations

In the world of pharmaceuticals, the formulation of medications is a critical step that directly impacts patient health. Pharmaceutical formulation facilities are the hubs where innovative practices and advancements are shaping the future of drug development. This blog explores the best practices and innovations that are revolutionizing pharmaceutical formulation facilities, ensuring the delivery of safe and effective medications to patients worldwide.

1. Introduction

Pharmaceutical formulation facilities stand at the crossroads of science, technology, and patient care. They are where pharmaceutical formulations come to life, and they play a pivotal role in the quality and efficacy of medications.

2. Advanced Formulation Technologies

2.1. Nanoscale Formulations

The pharmaceutical world is witnessing a revolution in nanoscale formulations. These formulations involve drug delivery systems at the nanometer scale. They bring groundbreaking changes by improving drug solubility, enhancing bioavailability, and enabling targeted drug delivery. This innovation opens the door to more effective treatments and reduced side effects for patients.

2.2. 3D Printing

In recent years, 3D printing has made a significant impact on pharmaceutical formulation. This technology allows for the precise fabrication of drug dosage forms, offering a level of customization never seen before. It paves the way for personalized medicine, unique drug delivery solutions, and the creation of complex drug structures that were once unimaginable.

3. Quality by Design (QbD)

The Quality by Design approach is a systematic and patient-centric method for designing and developing pharmaceutical formulations. It ensures that the quality of the final product is built into the manufacturing process from the very beginning.

3.1. Design Space

The concept of design space in QbD is a game-changer. It defines a multidimensional space within which various parameters can be adjusted, ensuring that the final product meets all quality attributes consistently. This approach enhances the robustness of manufacturing processes, making them more reliable and less prone to deviations.

3.2. Risk Assessment

Identifying and mitigating risks is a fundamental aspect of QbD. Pharmaceutical formulation facilities now incorporate risk assessment methodologies to proactively address potential issues. This proactive approach ensures that patient safety is prioritized, and the quality of medications remains uncompromised.

4. Continuous Manufacturing

The pharmaceutical industry is embracing continuous manufacturing as a transformative practice in formulation facilities. This approach replaces traditional batch processing with a continuous flow of materials. It offers numerous advantages, including enhanced control, reduced waste, and improved scalability. Continuous manufacturing aligns with the industry’s drive for efficiency and flexibility.

5. Automation and Industry 4.0

The infusion of automation and Industry 4.0 technologies in pharmaceutical formulation facilities is shaping a new era of drug development. Automated systems improve efficiency, reduce the risk of human error, and ensure precision in manufacturing processes.

5.1. Machine Learning and Artificial Intelligence

Machine learning and AI algorithms are being employed for predictive maintenance, quality control, and process optimization. These technologies can analyze vast datasets, identify trends, and make real-time adjustments to manufacturing processes to ensure the highest quality of medications.

5.2. IoT Integration

The Internet of Things (IoT) is making its way into pharmaceutical formulation facilities. Equipment and processes are interconnected, providing valuable data for optimizing operations and maintaining quality. Real-time monitoring and data analysis are becoming integral to quality control.

6. Sustainability Practices

Sustainability is no longer a buzzword but a genuine concern in the pharmaceutical industry. Pharmaceutical formulation facilities are adopting green practices to reduce their environmental footprint.

6.1. Eco-friendly Solvents

The use of eco-friendly solvents is a revolutionary step toward reducing the environmental impact of pharmaceutical formulation processes. These solvents are biodegradable, non-toxic, and safer for both workers and the environment.

6.2. Energy-Efficient Facilities

Pharmaceutical formulation facilities are designing energy-efficient buildings and processes to reduce their carbon footprint. Energy-efficient HVAC systems, optimized lighting, and responsible water usage are becoming standard practices.

7. Regulatory Compliance

Adherence to regulatory standards is a non-negotiable practice in pharmaceutical formulation. Facilities are committed to meeting and exceeding Good Manufacturing Practices (GMP) to ensure the safety and quality of medications.

7.1. GMP Compliance

Good Manufacturing Practices are the cornerstone of pharmaceutical formulation. They set high standards for product quality and safety, covering everything from personnel training to documentation and equipment validation.

7.2. Validation and Documentation

Comprehensive validation and documentation are vital for regulatory compliance. Every step of the formulation process must be thoroughly documented to meet industry and government standards.

8. Collaboration and Knowledge Sharing

The pharmaceutical industry understands that collaboration and knowledge sharing are indispensable in driving innovation. Companies are forming partnerships with research institutions, other pharmaceutical firms, and technology providers to tap into collective expertise and accelerate the development of new formulations.

Summary

Pharmaceutical formulation facilities are on the front lines of innovation. From the adoption of advanced formulation technologies to the integration of sustainable practices and the unwavering commitment to regulatory compliance, these facilities are the engines driving the development of safer, more effective medications.

In conclusion, pharmaceutical formulation facilities stand as beacons of hope for patients worldwide. Their commitment to embracing the latest technologies and best practices ensures that the pharmaceutical industry remains a source of healing, offering new possibilities and improved health for millions of people.

Comments are closed.