Laboratory Worksurfaces: Epoxy Resin vs Phenolic Resin

Work surface (or work top) material selection is among the most critical laboratory furniture decision. The intended application dictates material choices. Surfaces could be exposed to reagents and caustic substances. Heavy equipment may need to be supported or only light duty tasks may be performed.

Epoxy resin and Phenolic resin countertops or work surfaces are amongst the popular choices. However, when faced with a choice, many people are confused which one to choose – epoxy or phenolic resin.

In polymer chemistry and materials science, resin is a solid or highly viscous substance of plant or synthetic origin that is typically convertible into polymers. Resins are usually mixtures of organic compounds. Synthetic resins are industrially produced resins, typically viscous substances that convert into rigid polymers by the process of curing.

Though both Epoxy and Phenolic laboratory worktops are resins, they differ in the way they are made. In this blog, we will compare the properties, advantages, and disadvantages of both the materials. The comparison should help you choose the best material that fits your laboratory needs.

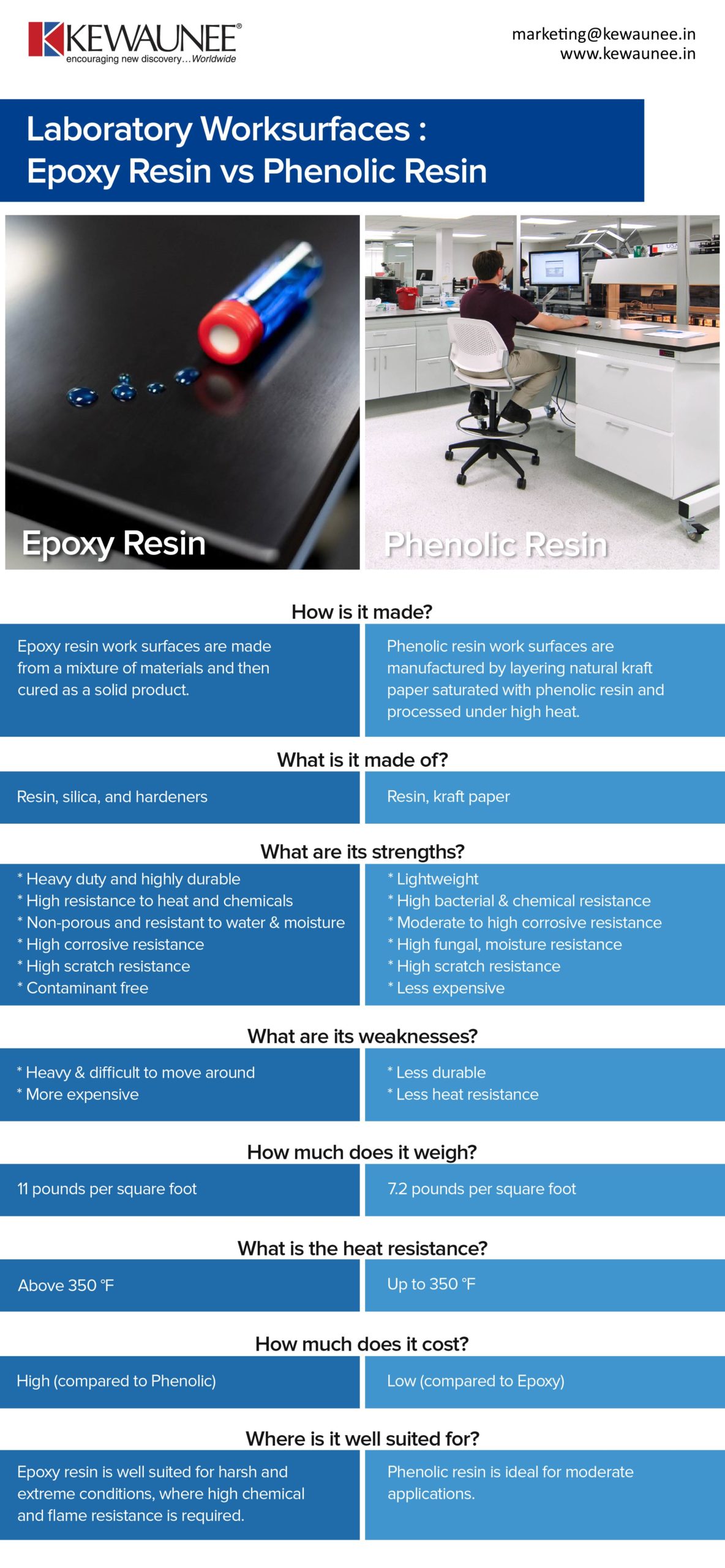

| EPOXY RESIN | PHENOLIC RESIN | |

|---|---|---|

| How is it made? | Epoxy resin work surfaces are made from a mixture of materials and then cured as a solid product. | Phenolic resin work surfaces are manufactured by layering natural kraft paper saturated with phenolic resin and processed under high heat. |

| What is it made of? | Resin, silica, and hardeners | Resin, kraft paper |

| What are its strengths? |

|

|

| What are its weaknesses? |

|

|

| How much does it weigh? | 11 pounds per square foot | 7.2 pounds per square foot |

| What is the heat resistance? | Above 350 °F | Up to 350 °F |

| How much does it cost? | High (compared to Phenolic) | Low (compared to Epoxy) |

| Where is it well suited for? | Epoxy resin is well suited for harsh and extreme conditions, where high chemical and flame resistance is required. | Phenolic resin is ideal for moderate applications. |

Comments are closed.