Flooring Material for Laboratory Environments

The flooring material in laboratory environments plays a crucial role in ensuring the safety, functionality, and productivity of the facility. Laboratories have unique requirements that demand careful consideration when selecting flooring options.

The right choice of flooring material can contribute to a safe, efficient, and compliant laboratory environment. This blog will explore the various considerations and options available for laboratory flooring to help professionals make informed decisions.

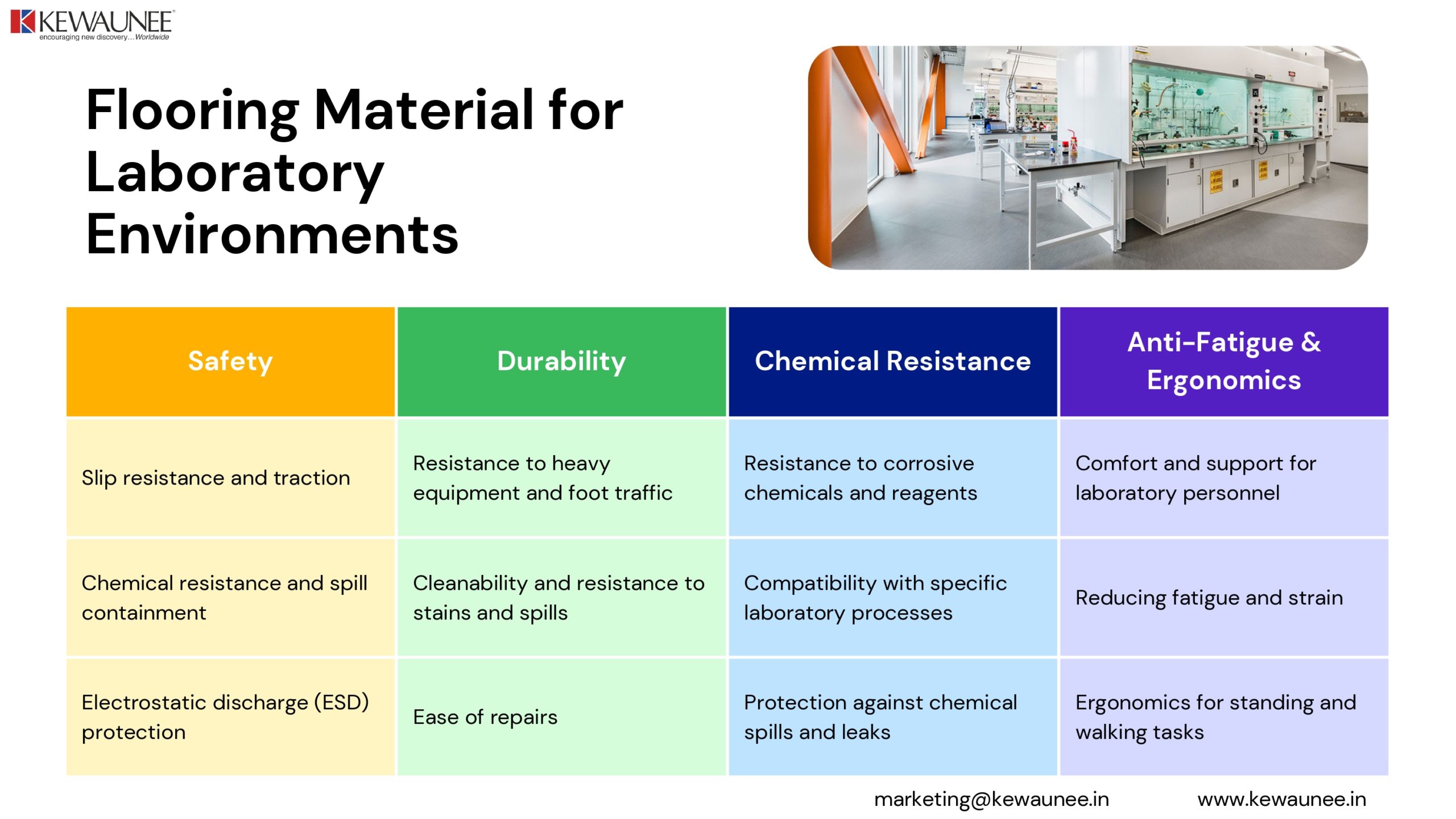

Choosing the right flooring material for a laboratory involves considering several factors, including safety, durability, chemical resistance, ergonomics, and maintenance requirements. Laboratory environments have specific needs that differ from other commercial or residential spaces.

Therefore, it is essential to explore the available options that address these unique challenges. This blog will provide an overview of the key considerations to keep in mind when selecting laboratory flooring materials and explore the range of options suitable for different laboratory areas.

Understanding the Challenges of Laboratory Flooring

A. Unique requirements and demands of laboratory environments

Laboratories have distinct requirements that pose challenges for flooring selection. These include the need for chemical resistance, protection against spills and leaks, slip resistance, static control, and fire resistance. Laboratory flooring must withstand heavy equipment, foot traffic, and potential impacts from dropped objects.

Additionally, it should adhere to regulatory standards and guidelines to ensure the safety of personnel and the integrity of experiments. Understanding these unique requirements is crucial for selecting the most suitable flooring material.

B. Impact of flooring on safety, functionality, and productivity

The choice of flooring material significantly impacts the safety, functionality, and productivity of laboratory environments. Slip-resistant flooring reduces the risk of accidents, while chemical-resistant flooring protects against corrosive substances and ensures easy cleanup. Proper ergonomic flooring design reduces fatigue and strain on personnel who spend long hours standing or walking.

A well-selected flooring material also contributes to the overall aesthetics and cleanliness of the laboratory, creating a conducive working environment. By considering these factors, laboratory managers can enhance safety, improve workflow, and boost productivity.

C. Compliance with regulatory standards and guidelines

Laboratories are subject to stringent regulatory standards and guidelines, such as those set by organizations like OSHA and EPA. Flooring materials must comply with these regulations to ensure a safe working environment. Compliance includes meeting slip resistance requirements, fire safety standards, and chemical resistance specifications.

Failure to adhere to these guidelines can result in penalties, compromised safety, and legal liabilities. Selecting flooring materials that meet or exceed regulatory standards is essential for maintaining compliance and safeguarding laboratory operations.

Safety Considerations for Laboratory Flooring

A. Slip resistance and traction properties

Slips and falls are common accidents in laboratories, and the choice of flooring material can play a significant role in preventing such incidents. Slip-resistant flooring with appropriate traction properties provides better grip and stability, reducing the risk of falls.

Factors such as the coefficient of friction, surface texture, and slip resistance ratings should be considered when selecting flooring materials. Assessing the laboratory’s specific slip resistance requirements is crucial for ensuring the safety of personnel.

B. Chemical resistance and spill containment

Laboratory flooring must be resistant to the chemicals and reagents used in experiments and processes. Chemical spills and leaks are common occurrences, and the flooring material should withstand exposure to corrosive substances without degrading or becoming damaged.

Additionally, proper spill containment measures, such as coved base options, should be considered to prevent spills from spreading and causing further hazards. Choosing chemically resistant flooring materials and implementing effective spill containment strategies are vital for maintaining a safe laboratory environment.

C. Electrostatic discharge (ESD) protection

ESD can pose a significant risk in laboratory environments, particularly in areas where sensitive electronic equipment or flammable materials are present. ESD flooring, such as conductive or dissipative flooring systems, helps to control static electricity and prevent electrostatic discharge that can damage equipment or cause explosions.

These specialized flooring options dissipate static charges safely, protecting both personnel and sensitive equipment from potential harm. Assessing the ESD requirements of the laboratory and selecting appropriate flooring materials is essential for mitigating the risks associated with static electricity.

D. Fire resistance and flammability ratings

Laboratories often handle flammable chemicals, and the risk of fire is a critical concern. Selecting flooring materials with high fire resistance and appropriate flammability ratings helps prevent the spread of fire and provides valuable evacuation time.

Fire-resistant flooring materials should be capable of withstanding high temperatures, resist burning, and emit low smoke and toxic fumes. Complying with fire safety regulations and implementing fire prevention measures, including the use of fire-resistant flooring, is essential to protect laboratory personnel and assets.

Durability and Maintenance

A. Resistance to heavy equipment and foot traffic

Laboratories are dynamic environments with heavy equipment and constant foot traffic. The flooring material should be durable enough to withstand the weight and movement of equipment, carts, and personnel. Choosing flooring materials with high load-bearing capacity and impact resistance is crucial to prevent damage and maintain a safe working environment.

Additionally, considering factors such as abrasion resistance and indentation resistance ensures the longevity of the flooring, reducing the need for frequent repairs or replacements.

B. Cleanability and resistance to stains and spills

Maintaining cleanliness and hygiene in laboratories is of utmost importance. The flooring material should be easy to clean and resistant to stains and spills. Smooth, non-porous surfaces prevent the absorption of chemicals or substances, making cleaning more efficient.

Choosing flooring materials with low porosity and chemical-resistant properties simplifies the removal of stains and enhances overall cleanliness. Proper cleaning protocols and routine maintenance are essential to preserve the integrity and cleanliness of the laboratory flooring.

C. Maintenance requirements and ease of repairs

Consideration should be given to the long-term maintenance requirements and ease of repairs for laboratory flooring. Some flooring materials may require specialized cleaning agents or specific maintenance procedures. Understanding the maintenance requirements, such as regular sealing or coating, helps ensure the flooring’s longevity.

Additionally, evaluating the ease of repairs, such as the ability to replace damaged sections without extensive disruptions to laboratory operations, is crucial. Opting for flooring materials that offer ease of maintenance and repair can save time, effort, and costs in the long run.

Chemical Resistance and Compatibility

A. Resistance to corrosive chemicals and reagents

Laboratories often handle a wide range of corrosive chemicals and reagents. The flooring material should exhibit high resistance to these substances to prevent degradation, staining, or damage.

Chemical-resistant flooring materials, such as epoxy or vinyl, provide a protective barrier against corrosive agents and ensure the durability of the flooring. Assessing the specific chemicals used in the laboratory and selecting flooring materials compatible with those chemicals is essential for maintaining a safe and long-lasting laboratory environment.

B. Compatibility with specific laboratory processes

Different laboratory processes may require specific flooring characteristics for optimal performance. For example, laboratories conducting experiments involving static-sensitive components or electronic equipment require ESD protection. In contrast, cleanrooms demand ultra-clean and particle-free flooring materials.

Understanding the compatibility requirements of specific laboratory processes helps in selecting flooring materials that support the efficient and safe execution of those processes. Ensuring that the chosen flooring material aligns with the specific needs of the laboratory processes enhances overall productivity and reliability.

C. Protection against chemical spills and leaks

Chemical spills and leaks can occur in laboratories, posing significant safety risks. The flooring material should provide a protective barrier against such incidents, preventing chemicals from seeping through or spreading. Impermeable and chemical-resistant flooring options help contain spills, allowing for easier cleanup and minimizing the risk of hazardous material exposure.

Implementing proper containment measures, such as bunding or secondary containment systems, in conjunction with chemically resistant flooring further enhances safety and mitigates the potential impact of spills or leaks.

Anti-Fatigue and Ergonomics

A. Importance of comfort and support for laboratory personnel

Laboratory personnel often spend long hours standing or walking, which can lead to fatigue and discomfort. Choosing flooring materials that prioritize comfort and support is crucial for the well-being and productivity of personnel.

Anti-fatigue flooring options, such as rubber or cushioned flooring, provide cushioning and shock absorption, reducing the strain on joints and muscles. By minimizing fatigue, these flooring materials contribute to improved focus, reduced injuries, and enhanced overall job satisfaction.

B. Impact of flooring on reducing fatigue and strain

The flooring material plays a vital role in reducing fatigue and strain on laboratory personnel. Hard, unforgiving surfaces can lead to discomfort and musculoskeletal issues over time. Ergonomically designed flooring options, such as those with cushioning or resilience, provide a more forgiving surface that absorbs impact and reduces strain on the body.

By minimizing the physical stress on personnel, ergonomic flooring contributes to increased comfort, decreased injury rates, and improved productivity in laboratory environments.

C. Ergonomic considerations for standing and walking tasks

Laboratory tasks often involve repetitive standing or walking, which can cause strain on the legs, feet, and lower back. Considering ergonomic factors when selecting flooring materials helps create a more supportive and comfortable workspace.

Ergonomic flooring options provide cushioning and resilience, reducing the impact on joints and muscles during prolonged standing or walking. Additionally, anti-slip properties enhance safety by reducing the risk of slips and falls. Taking into account the specific tasks and movements required in the laboratory environment allows for the implementation of flooring solutions that optimize ergonomics and promote the well-being of laboratory personnel.

Specialty Flooring Options for Laboratories

A. Epoxy and resin-based flooring systems

Epoxy and resin-based flooring systems are popular choices for laboratory environments due to their exceptional durability, chemical resistance, and ease of maintenance. These flooring options provide a seamless and smooth surface that is resistant to chemicals, stains, and abrasion. Epoxy floors are highly customizable, allowing for different colors, textures, and patterns to match the laboratory’s aesthetic requirements.

They are also known for their high-gloss finish, which enhances visibility and brightness in the workspace. Resin-based flooring systems offer similar benefits and can be formulated to meet specific performance requirements, such as anti-static properties or antimicrobial protection. Overall, epoxy and resin-based flooring systems offer a reliable and versatile solution for laboratory environments.

B. Static-control flooring for sensitive environments

Laboratories dealing with sensitive electronic equipment or processes require flooring materials that prevent the build-up and discharge of static electricity. Static-control flooring, such as conductive or dissipative flooring, offers protection against electrostatic discharge (ESD). These flooring options have specialized properties that safely ground or dissipate static charges, minimizing the risk of damaging sensitive equipment or compromising delicate experiments.

Static-control flooring is available in various forms, including vinyl, rubber, or epoxy, and can be customized to meet the specific ESD requirements of the laboratory environment. Implementing static-control flooring ensures the integrity and reliability of electronic components and promotes a safe working environment.

C. Conductive and dissipative flooring for ESD protection

In addition to static-control flooring, laboratories working with explosive or flammable materials may require flooring materials with a higher level of conductivity. Conductive flooring provides a lower electrical resistance path to safely dissipate any potential static charges. This type of flooring prevents the accumulation of static electricity, reducing the risk of sparks that could ignite flammable substances.

Dissipative flooring, on the other hand, offers an intermediate level of electrical resistance, allowing for controlled dissipation of static charges. Choosing the appropriate level of conductivity depends on the specific hazards present in the laboratory environment. Conductive and dissipative flooring options provide an added layer of protection against static-related risks, ensuring the safety and integrity of sensitive processes and materials.

Flooring Selection for Different Laboratory Areas

A. Wet laboratory areas and chemical storage rooms

Wet laboratory areas and chemical storage rooms require flooring materials that can withstand exposure to water, chemicals, and potential spills. Non-slip flooring options, such as those with textured surfaces or slip-resistant coatings, are crucial to prevent accidents in wet environments.

Additionally, chemical-resistant flooring materials, such as epoxy or vinyl, are highly suitable for these areas due to their ability to withstand corrosive substances and ease of cleaning. The flooring should be impermeable, preventing any liquids from seeping into the underlying layers and causing damage. Ensuring proper drainage systems and implementing containment measures, such as floor bunding or curbs, further enhances safety in wet laboratory areas and chemical storage rooms.

B. Cleanrooms and controlled environments

Cleanrooms and controlled environments demand flooring materials that meet stringent cleanliness and particle control requirements. These areas require flooring with ultra-smooth and non-porous surfaces to prevent the accumulation of contaminants. Materials such as epoxy, vinyl, or linoleum, known for their low particle emission and high cleanability, are commonly used in cleanroom applications.

The flooring should also have tight seams and minimal joints to minimize the risk of particle accumulation and facilitate easy cleaning. Antimicrobial and anti-static properties may also be necessary depending on the specific cleanroom classification and requirements. Selecting flooring materials that comply with cleanroom standards ensures the maintenance of strict environmental conditions and the integrity of sensitive processes conducted within these controlled environments.

C. Instrumentation and equipment rooms

Instrumentation and equipment rooms house delicate and expensive equipment that requires protection against vibrations and impact. Floating floors, which consist of a raised flooring system supported by a spring or foam layer, are often employed in these areas to provide enhanced shock absorption and vibration isolation.

This type of flooring reduces the transfer of vibrations from equipment or foot traffic, preventing potential damage to sensitive instruments. Anti-static properties may also be necessary to protect electronic equipment from static discharge.

Additionally, ergonomic considerations should be taken into account to provide a comfortable and safe working environment for personnel operating the equipment. Proper flooring selection in instrumentation and equipment rooms ensures the longevity and performance of the machinery while maintaining a controlled and functional workspace.

D. Office and administrative spaces

While laboratory flooring requirements typically focus on safety, durability, and functionality, the flooring in office and administrative spaces within the laboratory plays a role in creating a comfortable and aesthetically pleasing environment. In these areas, the emphasis may be on flooring options that contribute to a professional and welcoming atmosphere.

Common choices for office spaces include carpet tiles, luxury vinyl tiles (LVT), or hardwood flooring. These options offer design flexibility, ease of maintenance, and acoustic benefits. Comfort and ergonomics should also be considered, especially for areas where personnel spend extended periods seated at desks or workstations.

Incorporating ergonomic flooring features, such as cushioning underlay or anti-fatigue mats, can enhance comfort and reduce the risk of strain-related injuries. Choosing the appropriate flooring materials for office and administrative spaces contributes to a cohesive and harmonious laboratory environment.

Environmental Considerations

A. Sustainability and eco-friendly flooring options

In today’s environmentally conscious world, the selection of sustainable and eco-friendly flooring materials has become increasingly important. Laboratory facilities can contribute to sustainability goals by opting for flooring options that minimize their environmental impact. Sustainable flooring materials, such as bamboo, cork, or linoleum, are derived from renewable resources and have low environmental footprints.

These materials are typically manufactured using environmentally friendly processes and do not emit harmful chemicals or volatile organic compounds (VOCs). Additionally, selecting flooring options with high recycled content or those that can be easily recycled at the end of their life cycle further promotes sustainability. By choosing eco-friendly flooring materials, laboratories can reduce their carbon footprint and contribute to a healthier and more sustainable environment.

B. Indoor air quality and VOC emissions

Indoor air quality is a crucial consideration in laboratory environments, as it directly impacts the health and well-being of laboratory personnel. Flooring materials can emit volatile organic compounds (VOCs) that contribute to poor indoor air quality. VOCs are released as gases from certain solids or liquids, including some flooring materials, adhesives, or finishes.

Laboratories should prioritize flooring options with low VOC emissions to minimize potential health risks. Flooring materials that have been certified by recognized programs, such as FloorScore or GREENGUARD, indicate compliance with stringent VOC emission standards. These certifications provide assurance that the flooring materials have undergone testing and meet the required indoor air quality criteria. By selecting flooring options with low VOC emissions, laboratories can create a healthier and more comfortable environment for their personnel.

C. LEED certification and green building practices

Laboratory facilities seeking to demonstrate their commitment to sustainable building practices may pursue Leadership in Energy and Environmental Design (LEED) certification. LEED is a globally recognized rating system that evaluates the sustainability and environmental performance of buildings. Flooring material selection plays a significant role in achieving LEED certification.

Laboratories can earn points toward certification by using flooring materials that meet specific criteria, such as recycled content, regional sourcing, or low-emitting properties. LEED-certified flooring options often include recycled materials, rapidly renewable resources, or low-emitting adhesives. By incorporating LEED-certified flooring materials and following green building practices, laboratories can contribute to a more sustainable future and align with environmentally responsible standards.

Cost Considerations

A. Initial installation costs

When considering flooring options for laboratory environments, it is important to assess the initial installation costs. The cost of flooring materials can vary significantly depending on the type, quality, and specifications of the chosen flooring option. Specialty flooring materials designed for laboratory environments, such as epoxy or conductive flooring, may come at a higher price due to their unique properties and performance characteristics.

It is essential to balance the desired features and benefits of the flooring materials with the available budget. Laboratories should consider the long-term value and return on investment that the chosen flooring option can provide. While some flooring options may have higher upfront costs, they may offer greater durability, ease of maintenance, and longevity, resulting in potential cost savings over the life cycle of the flooring.

B. Lifecycle costs and long-term durability

Beyond the initial installation costs, laboratories should also consider the lifecycle costs and long-term durability of the selected flooring materials. High-quality flooring options that are specifically designed for laboratory environments tend to have superior durability and resistance to wear and tear. These materials can withstand heavy foot traffic, frequent cleaning, and exposure to chemicals without requiring frequent repairs or replacement.

By investing in durable flooring options upfront, laboratories can minimize the need for ongoing maintenance and reduce the costs associated with frequent replacements. It is important to assess the expected lifespan of the flooring materials and consider factors such as warranties and maintenance requirements. Evaluating the long-term durability and lifecycle costs helps laboratories make informed decisions that optimize both budget and performance.

C. Return on investment and cost-effectiveness

Choosing the right flooring material for laboratory environments is not solely about upfront costs or durability; it also involves assessing the overall return on investment (ROI) and cost-effectiveness. The selected flooring should align with the specific needs and requirements of the laboratory, providing tangible benefits that contribute to the efficiency, safety, and productivity of the workspace.

Factors such as reduced maintenance requirements, increased longevity, improved safety, and enhanced productivity should be taken into consideration when evaluating the ROI of the chosen flooring option. Laboratories should weigh the initial investment against the long-term benefits and savings that the flooring materials can deliver.

Additionally, selecting flooring options that offer versatility and adaptability can further enhance cost-effectiveness by accommodating future changes or expansions in the laboratory. By considering the overall ROI and cost-effectiveness, laboratories can make well-informed decisions that optimize the value and performance of their flooring investments.

Flooring Maintenance and Care

A. Cleaning protocols and practices

Proper cleaning protocols and practices are essential to maintain the longevity and performance of laboratory flooring. Regular cleaning routines should be established, taking into account the specific requirements and recommendations provided by the flooring manufacturer. Different flooring materials may have varying cleaning instructions, including the use of specific cleaning agents, equipment, or techniques. Laboratories should ensure that cleaning products are compatible with the flooring materials and do not compromise their integrity or performance.

Additionally, prompt cleaning of spills, stains, or chemical splashes is crucial to prevent potential damage. Laboratories may implement the use of absorbent mats or spill containment measures to minimize the spread of liquids and protect the flooring. Proper training and education of laboratory personnel on appropriate cleaning protocols and practices are essential to maintain a clean and safe working environment.

B. Maintenance schedules and preventive measures

Establishing regular maintenance schedules and implementing preventive measures is key to prolonging the life of laboratory flooring. This includes conducting routine inspections to identify any signs of wear, damage, or potential hazards. Laboratories should address any issues promptly to prevent further damage or safety risks.

Preventive maintenance measures may include applying protective coatings or sealants to enhance the durability and chemical resistance of the flooring, as well as conducting periodic maintenance activities such as buffing, polishing, or resealing, depending on the type of flooring material.

Laboratories should also ensure that proper care is taken when moving heavy equipment or conducting any activities that may cause impact or damage to the flooring. By implementing proactive maintenance strategies, laboratories can extend the lifespan of their flooring and minimize the need for costly repairs or replacements.

C. Repairs and refurbishment

Over time, laboratory flooring may require repairs or refurbishment to address wear and tear, damage, or changes in requirements. It is important to work with experienced professionals or flooring experts to assess the extent of the damage and determine the appropriate repair or refurbishment approach.

Depending on the flooring material, repairs may involve patching damaged areas, reapplying coatings or finishes, or replacing sections of the flooring. Laboratories should ensure that the repair materials or replacement components match the original flooring to maintain consistency in performance and appearance.

Refurbishment projects may include deep cleaning, resealing, or refinishing the flooring to restore its original properties and extend its lifespan. Regular inspections and timely repairs or refurbishment can help laboratories maintain a safe, functional, and visually appealing flooring environment.

Conclusion

In conclusion, selecting the right flooring for laboratory environments requires careful consideration of various factors, including safety, durability, functionality, and environmental impact.

From wet laboratory areas to cleanrooms, instrumentation rooms to office spaces, each area within the laboratory has unique requirements that must be addressed. Understanding the specific needs of the laboratory and considering factors such as specialty flooring options, environmental considerations, cost considerations, and maintenance practices will help laboratories make informed decisions and create optimal working environments.

By investing in suitable flooring solutions and implementing proper maintenance and care, laboratories can enhance safety, productivity, and the overall efficiency of their operations.

Comments are closed.