Chennai’s Laboratory Landscape and Safety Expectations

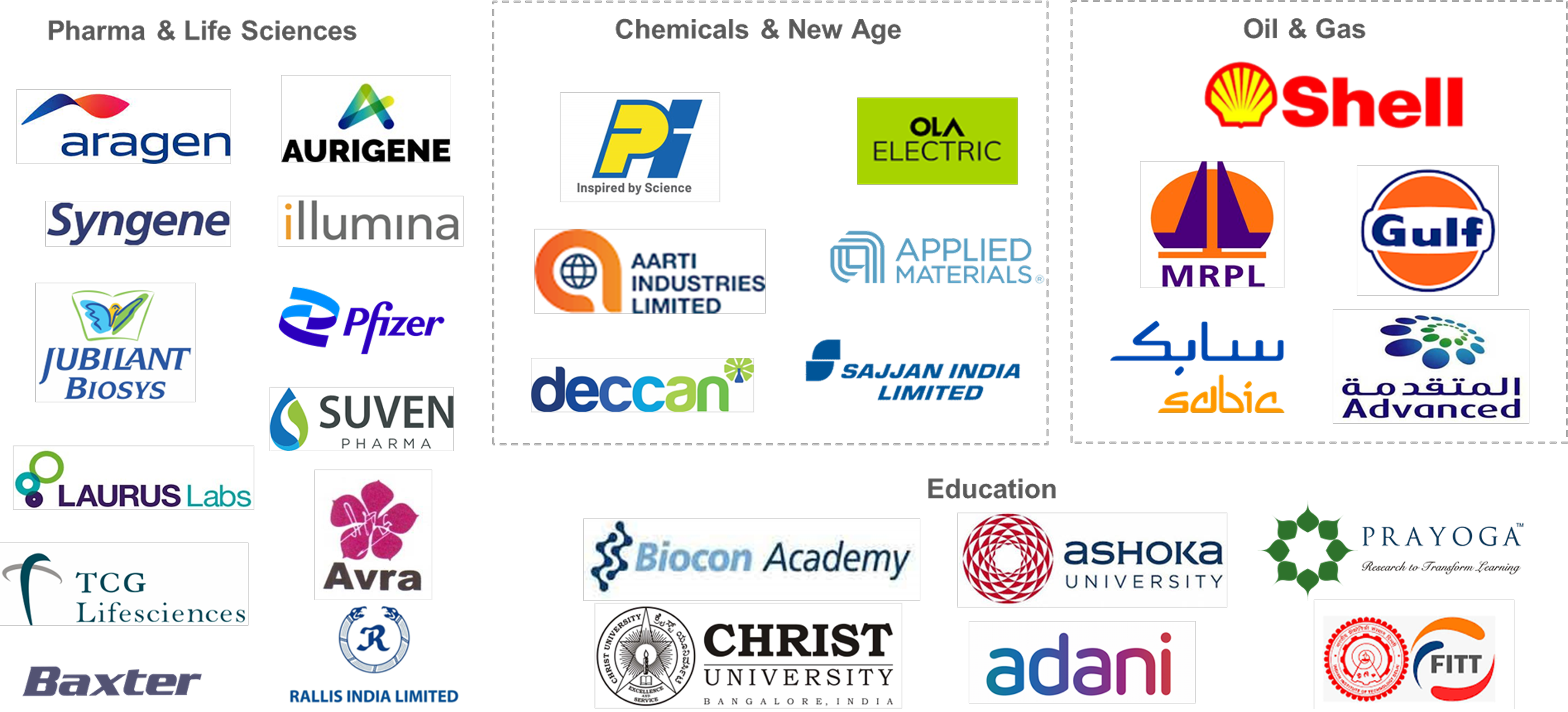

Laboratories in Chennai support diverse industries, from large-scale pharmaceutical manufacturing to advanced R&D centres and educational institutions. Each of these environments faces strict safety norms and high daily usage.

Chemical exposure, variable workloads, and frequent procedural changes demand containment systems that perform consistently. This is where experienced fume hood manufacturers in Chennai make a measurable difference. Kewaunee designs systems that maintain containment stability across changing conditions, supporting safe operations without interrupting workflow.